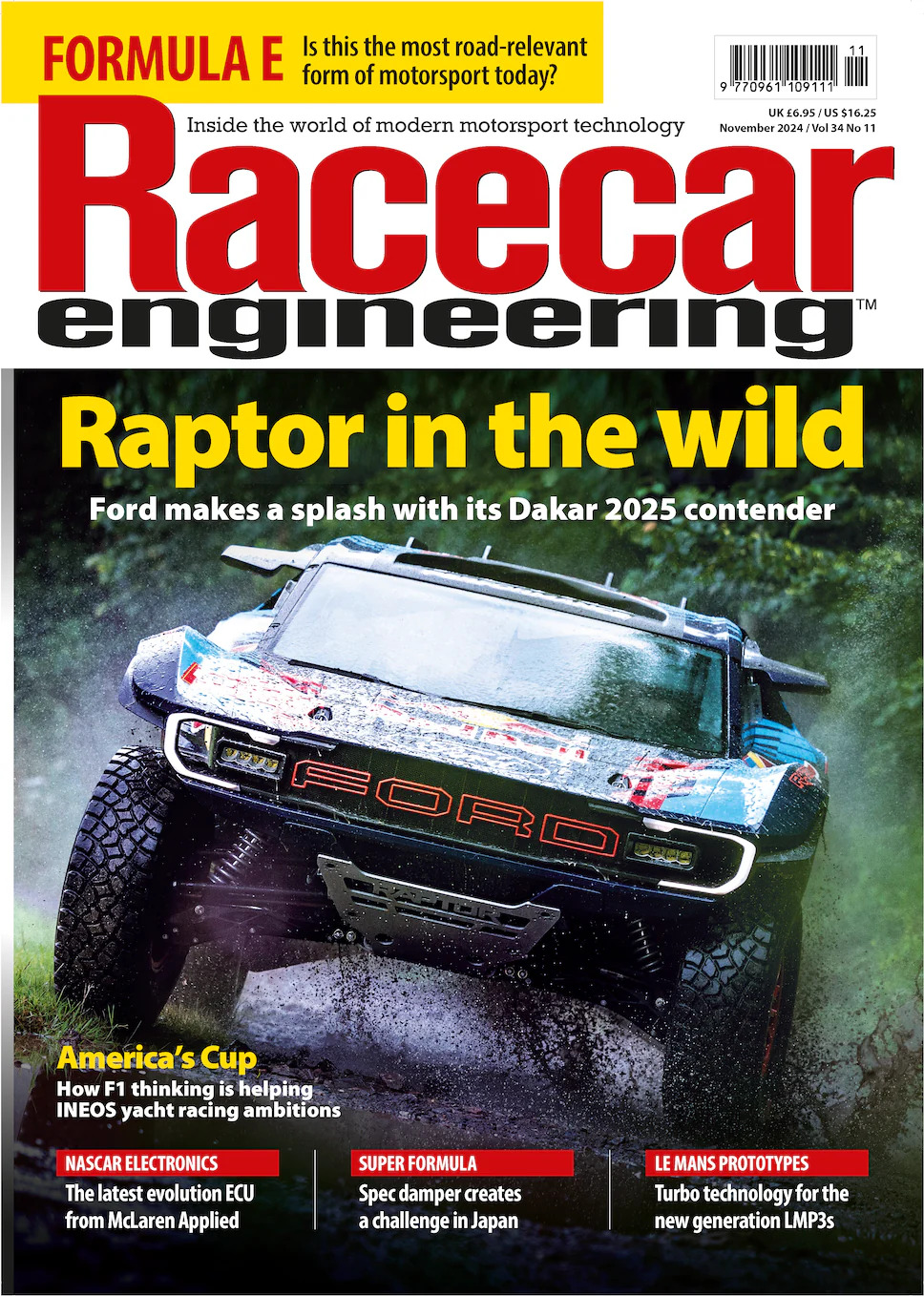

“It’s a brand new car from the ground-up – everything is new” explains Force India Technical Director Andrew Green of the VJM06. “We discussed carrying over big chunks of last year’s car, including the chassis, but decided not to. There were still some gains to be had with the chassis, so we elected to take the performance benefits. However, the car is evolution rather than revolution compared with last year, simply because of the nature of the regulations.

There are quite a few large changes under the skin. Because we focussed a lot on the tyres last year, we’ve given ourselves a few more options on set-up to help manage them from qualifying to the race. So that’s something we will focus on going into winter testing – we’ll be looking at those options and trying to understand them. It’s going to be a challenge assessing these during the cold winter tests, but those options will give the engineers more weapons in their armoury.”

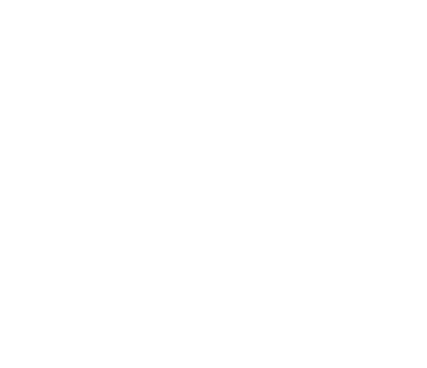

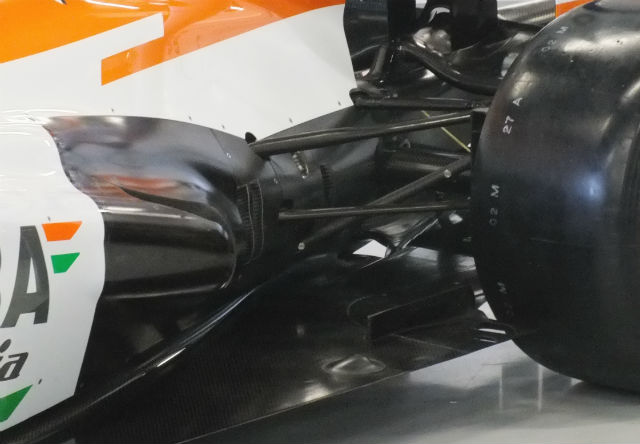

One of the major areas of change is in the rear suspension, which uses different pickup points on the McLaren gearbox casing compared to the VJM05. It remains a pull rod layout however. “The suspension has been tuned for what we learned on the tyres, so the configuration is different to last year with changes aimed at better complementing the tyres. The rear suspension is quite different – for aerodynamic reasons the whole thing has been lifted up to allow the airflow under the lower rear wishbones” Green explains.

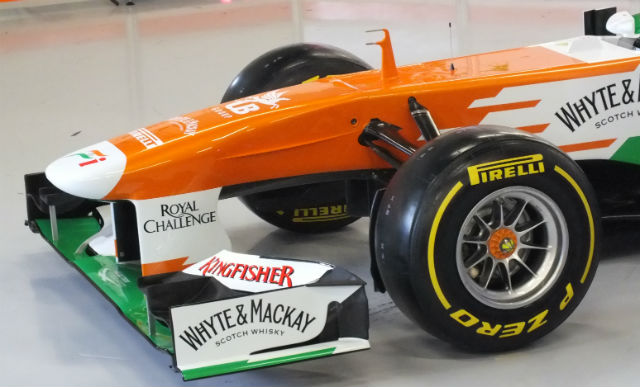

At the front of the car the team has opted to use one of the vanity panels, this is a single ply carbon fibre skin with just 3mm of honeycomb in it. It weighs just a few grams and gives a minor aerodynamic gain. Note the interesting strake on the side of the nose. The nose itself features a bulge on the underside seen on the VJM04 and the 2012 Lotus. It is noticeably different to the 2012 design (below)

Another area of the car to be substantially revised is the roll over structure, for a few years Force India had used a design with four exposed legs (below) which first appeared in 2010. The Sauber C30 of 2011 copied the design.

The new design is quite different with the rear supports shrouded and clearly a different shape. Green has revealed that the centre of gravity of the 2013 car is slightly lower so it is likely that this redesign of the roll hoop is part of the efforts to lower it.

The exhaust design follows the same concept as it did in 2012 but with the addition of a so called Helmholtz chamber which regains some of the power loss incurred by using a blown diffuser style exhaust layout.

This type of exhaust requires a very different approach for the drivers something that Force India is working on in the simulator. If it signs a driver without experience of driving with one of these layouts which lose a lot of rear downforce when the driver is off the throttle he will almost certainly struggle initially.

Both the front and rear suspension have been redesigned to allow the car to work better with the tyres, the rear wishbones have been raised and the fronts have also been relocated though the car retains the same wheelbase.

A new development for Force India is interlinked suspension, popular with front running teams it stabilises the car in aerodynamic terms. The front and rear dampers are hydraulically linked but the system is not as sophisticated as the one used by Mercedes. It will not be installed on the car initially but the car has been designed for it and once the team is happy with its performance then it will be fitted.

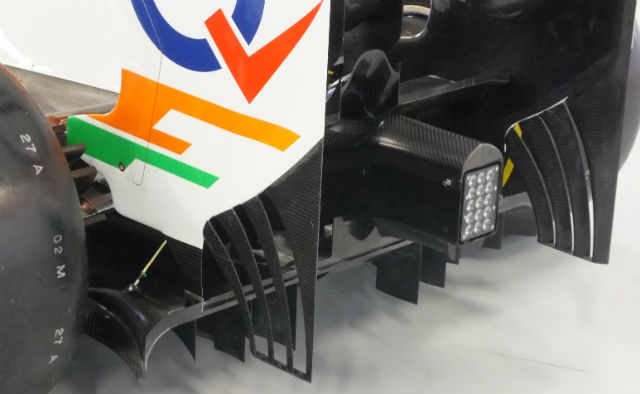

The diffuser on the launch car is largely a carry over from the 2012 model but the ‘monkey seat’ winglet is far more elaborate.

TEST 00: Silverstone (Shakedown)

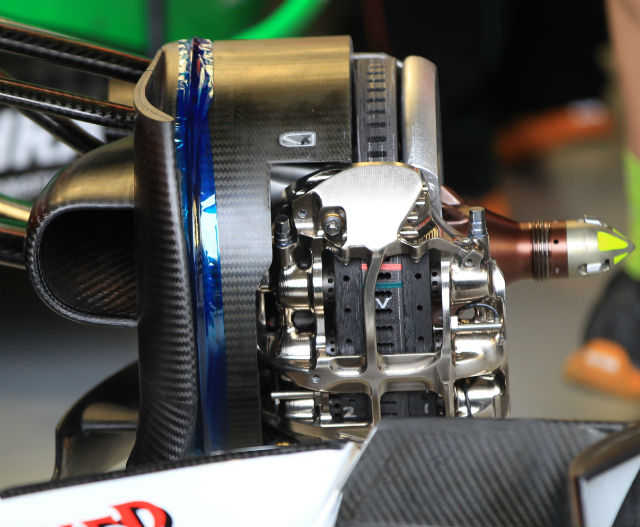

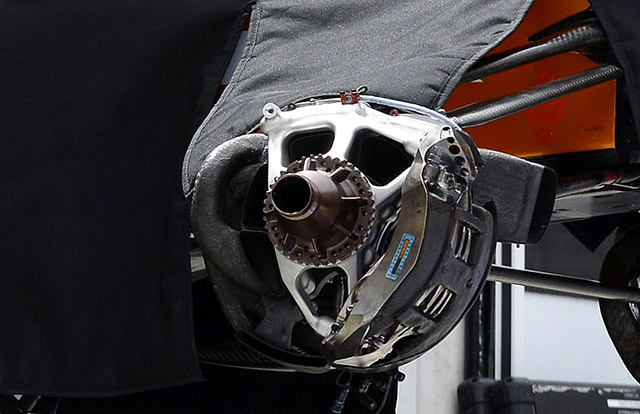

The cold and wet conditions meant that the VJM06 did not get much running done with less than a handful of laps. But it did give us the chance to have a look at the cars front brake set up. Note the drilling patterns in the disc and pads, teams change these throughout the year depending on the circuit, conditions and driver preference.

TEST 01: JEREZ

Chassis: VJM06-02

“We leave Jerez feeling pretty satisfied with the work we have completed and what we have learned about the VJM06. We’ve completed a lot of aero mapping and carried out a big tyre evaluation programme, so reviewing all that data will be our focus in the build-up to the Barcelona test. It’s good that we have a ten-day break because that should give us enough time to evaluate our performance and really understand where we stand. As always, the trackside guys have worked incredibly hard this week, supported by the factory, and that has allowed us to maximise the time on track with the new car.” Jakob Andreasen, Chief Race Engineer

At Jerez it was possible to get a glimpse of the Force India’s front bulkhead. The torsion bars, power steering and master cylinder are all visible, as is what appears to be a nose fed driver cooling duct at the base of the chassis between the lower wishbone pickups.

The nose of the VJM06 has a curious shape when studied from above

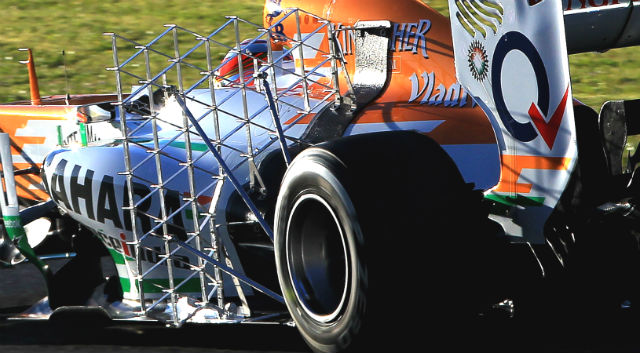

A huge array of pitot tubes was fitted to the car at the end of its first test as the team tries to understand the flows around the car. It is likely that this test will be repeated using CFD and possibly PIV at the TMG tunnel in Cologne.

Flow visualisation runs were conducted on the rear wing as part of the aerodynamic programme.

TEST 02: BARCELONA

Chassis: VJM06-03

A solid second test for Force India at Barcelona saw the team test drivers and attempt some tyre evaluations. An aero programme was conducted with a few new components.

A small array was fitted ahead of the rear wheel to measure the flow in that region. It is clearly positioned to measure the air flow in the exhaust plume.

The larger array used at Jerez made a reappearance also.

Force India studied the rear floor of the car using temperature strips. This is crucial to understanding the exhaust flow. Note the vent in the rear wing endplate. These are increasingly common on many of the cars.

An updated front wing was introduced at the final test. Whilst similar in overall design it features an additional element similar to those used on recent McLaren’s. Compare the new wing (above) with the old (below)

Flow vis dye was used to evaluate the flow structures from the new front wing. Note the areas licked by the flow from the wing, the mirror, the tyre sidewall and interestingly and a rear wing.

Flow vis dye was used to evaluate the flow structures from the new front wing. Note the areas licked by the flow from the wing, the mirror, the tyre sidewall and interestingly and a rear wing.

TEST 02: BARCELONA

Chassis: VJM06-03

Some parts of the bodywork have been showing signs of getting too hot despite the cool conditions a Barcelona. Note the burn marks on the white sections of bodywork

RACE 01: ALBERT PARK, MELBOURNE, AUSTRALIA

Car: 14

Chassis: VJM06/04

Result: 8th

Car: 15

Chassis: VJM06/03

Result: 7th

The strong finish at Albert Park will make it hard for Force India to divide resources between its 2014 project which is behind schedule and the 2013 constructors championship which looks like it could yield much needed cash in prize money.

RACE 02: SEPANG, SELANGOR, MALAYSIA

Car: 14

Chassis: VJM06/04

Result: DNF (wheel nuts)

Car: 15

Chassis: VJM06/03

Result: DNF (wheel nuts)

Problems with the teams new captive wheel nuts saw both cars retire from the race.

RACE 03: JIADING, SHANGHAI, CHINA

Car: 14

Chassis: VJM06/04

Result: 8th

Car: 15

Chassis: VJM06/03

Result: DNF (Collision)

RACE 04: SAKHIR, BAHRAIN

Car: 14

Chassis: VJM06/04

Result: 4th

Car: 15

Chassis: VJM06/03

Result: 13th

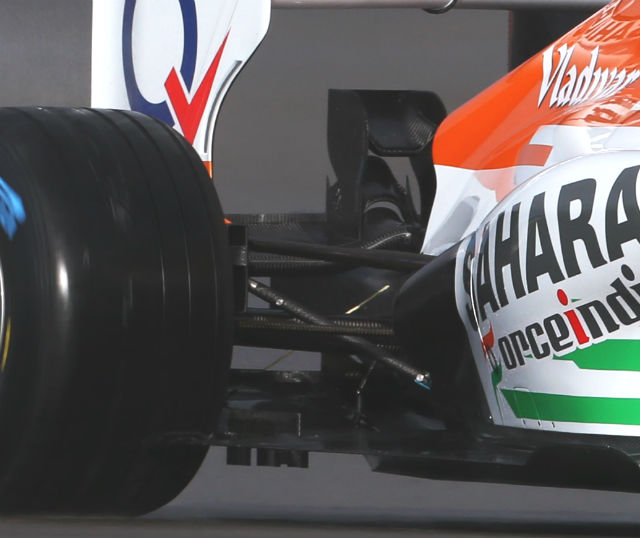

A nice look at the uprights on the VJM06 with the brake discs removed.

Read more in the September 2012 issue of Racecar Engineering