Red Bull Racing RB15

Red Bull have had the monumental challenge of integrating a completely different power unit as well as all the ancillaries into this year’s RB15. Running with the Honda power unit for the very first time, it’s fair to say that Red Bull seemed to have coped with the switch very well. The Honda unit is not only competitive, but also reliable, as proven by the minimal (if any) power unit related issues so far. However, with Red Bull notorious for maximising every millimetre of space in their tightly-packaged racecars – will this reliability and performance continue?

Keep up to date with all of RB15‘s developments as we delve into the technical secrets behind this year’s Red Bull contender as well as all the technical updates throughout the season. And knowing Red Bull – there will be many!

-

Red Bull RB15 Bahrain Tech update

-

Red Bull RB15 Australia Tech update

-

Red Bull RB15 testing update

-

Red Bull RB15 launch

Red Bull RB15 Bahrain Tech update

Red Bull Racing ran several prototype camera mount designs on the front suspension throughout Friday’s practice sessions at the Bahrain GP. These could potentially be gathering data on tyre surface temperature, rim temperature or front wing deflection.

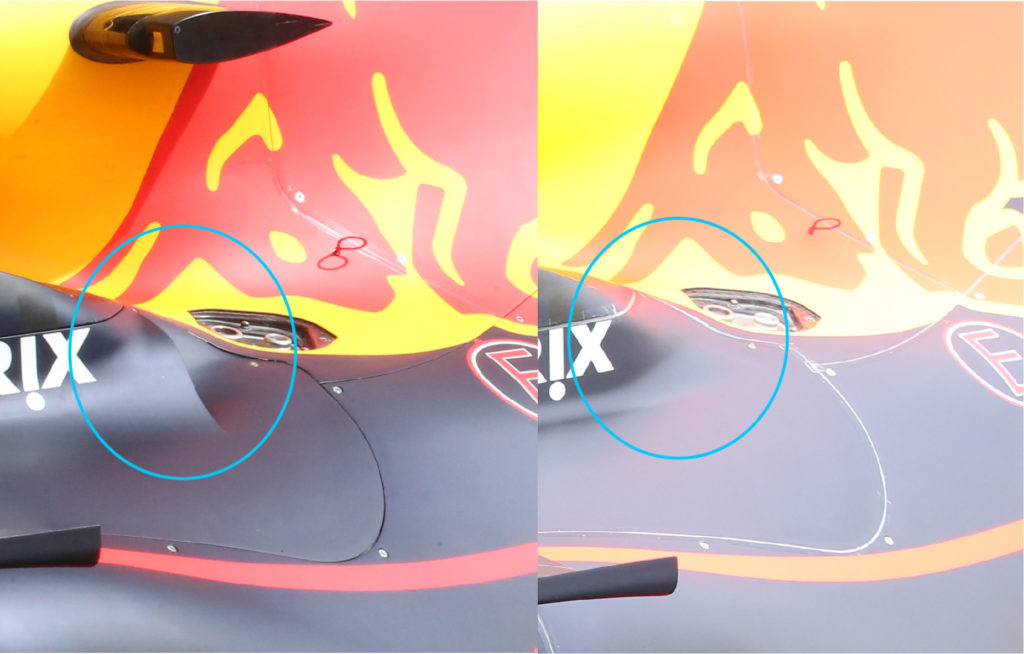

For the majority of last year, Mercedes ran with a small vent behind the rear mounting of the Halo. At this year’s Bahrain GP, the Red Bull RB15 featured a similar design.

As the Halo is a solid titanium structure there is no way for air to flow through it. Therefore, teams can’t be extracting air from the front of the car and feeding it up through the nose, exiting at the rear of the Halo, in a similar vein to how the S-duct works. So, this vent could be fed by another airflow either from the cockpit itself, or through the cockpit. However, this is puzzling. The airflow in and around the cockpit area is very turbulent, therefore ‘dirty’ air from other areas of the car are often fed into the cockpit as it has the least negative effect on the overall aerodynamic performance. This is the reasoning behind the S-duct. So why would teams want to extract this turbulent air and direct it towards the rear wing? Unless this is simply to offer some form of cooling/ventilation to reduce cockpit temperatures, improving driver comfort at the hotter races.

Red Bull RB15 Australia Tech update

Despite the quick turnaround between pre-season testing and the first Grand Prix of the season, the RB15 arrived in Australia with quite a few tech updates.

Starting at the front, the majority of front wing designs were very similar to what was revealed during pre-season testing. With such a tight turnaround, modifying the front wing can be risky as any change can completely change the behaviour of the airflow, affecting the performance of all the other aerodynamic devices downstream. Despite this, Red Bull made a very minor alteration to the RB15‘s front wing endplates as highlighted in blue below.

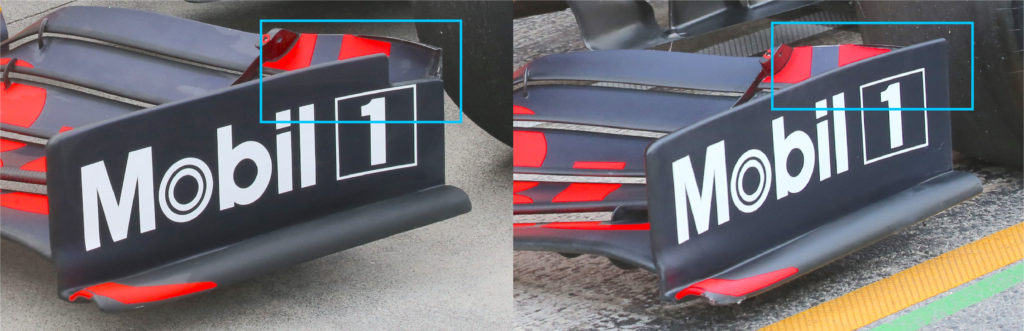

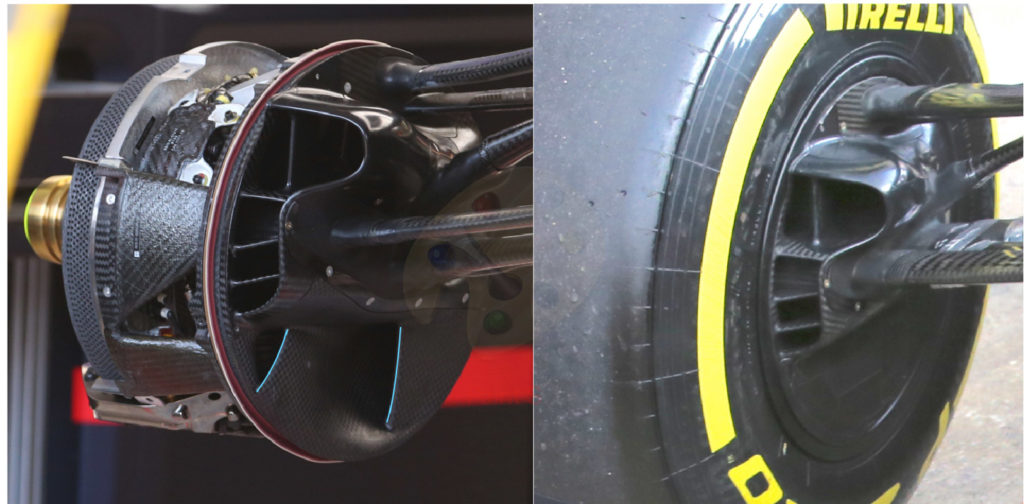

As was discussed at pre-season testing, the 2019 regulations heavily restrict the front brake duct design, which is why this will be a significant area of development as teams attempt to extract the maximum performance out of this area. An iteration of designs can already be seen on Red Bull’s RB15. During the 1st pre-season test, the area below the front brake duct was flush with the wheel rim and had no inlets or additional elements (below right). However, at the 2nd pre-season test, one vertical inlet near the centreline of the wheel was added. By the time the car arrived in Australia, an additional, smaller inlet was also integrated directly below the front brake duct, with both inlets highlighted in blue below.

The teams are always pushing to flow air through the wheel, from the inboard to the outboard side because this is a very powerful mechanism to help steer the front wing wake wider and therefore further away from the car. In doing this, the wake of the front wing has minimal interaction with the wake from the front wheel and overall the aim is to minimise the amount of turbulent airflow that goes onto the rear wing and diffuser, which reduces the performance of these aerodynamic devices. Air through the wheel assembly is also used to cool the brakes and this hot air can then be manipulated to heat the rim and therefore help with tyre warm up.

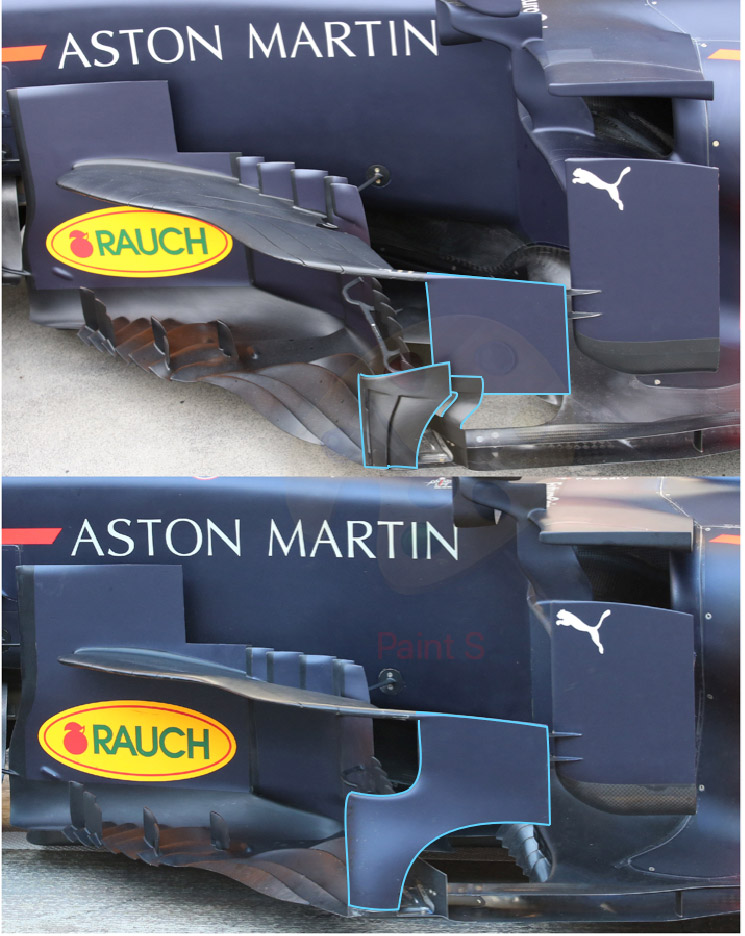

Another change was the updated bargeboard design. The RB15 featured an additional element with two vertical slots as opposed to the one piece solution seen at pre-season testing, highlighted in blue below.

It is rare to see the inner workings of the engine air intake, but here we have a detailed shot of the layout on the RB15. It’s interesting to note that there are two inlets that are mounted on top of one another. The top inlet provides air to the main radiator above the power unit, while the bottom inlet feeds more air into the depths of the PU.

Keep up to date with all the latest motorsport technology with a Racecar Engineering subscription