Ferrari SF90

2019 marks another era of change for the Ferrari team. Not only has Maurizio Arrivabene been replaced by new Team Principal, Mattia Binotto, formerly Ferrari’s Chief Technical Officer. But also, Kimi Raikkonen has swapped seats with F1’s new young gun Charles Leclerc, who lines up alongside Sebastian Vettel.

In terms of the machinery they will both be driving, the secrets of the SF90 are hidden under the usual cloak of secrecy from Ferrari. However, we do know that packaging has been a key focus, with the refining and relocating of engine components resulting in a much narrower engine cover and bodywork design. Furthermore, fluid dynamic development has ensured that despite taking up less space, the same level of cooling efficiency as last year has still been achieved.

This page will delve into the technical secrets behind this year’s Ferrari SF90 F1 car as well as the technical updates that Ferrari will add throughout the season.

-

Ferrari SF90 Chinese Tech update

-

Ferrari SF90 Bahrain Tech update

-

Ferrari SF90 testing update

-

Ferrari SF90 launch

Ferrari SF90 Chinese Tech update

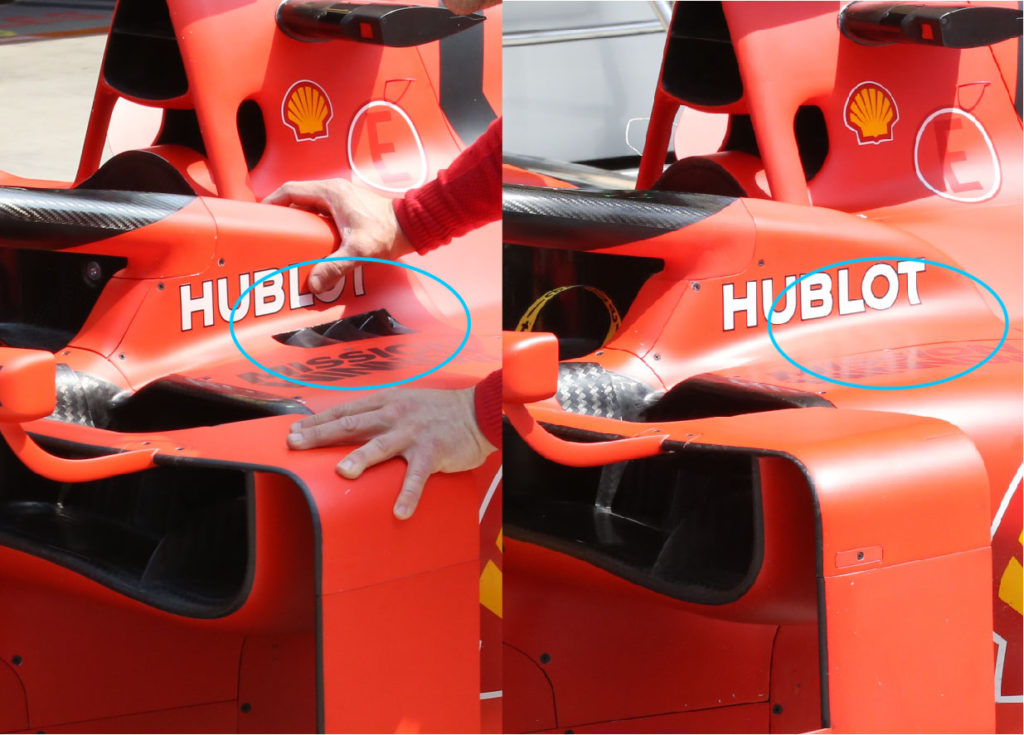

With track temperatures reaching 41degC, the teams often open up their cooling vents to maximise the amount of air flowing through their cooling system to achieve maximum heat rejection from the car, as illustrated by the Ferrari SF90.

Another form of cooling is to flow air through the wheel assembly. This not only cools the brakes but also uses this heat energy from the brakes to increase the temperature of the rim, which in turn helps to warm the tyres into their operating window. Air through the wheel also helps to guide any turbulent wakes away from the car, avoiding this ‘messy’ air flowing downstream onto the rear wing.

Ferrari SF90 Bahrain Tech update

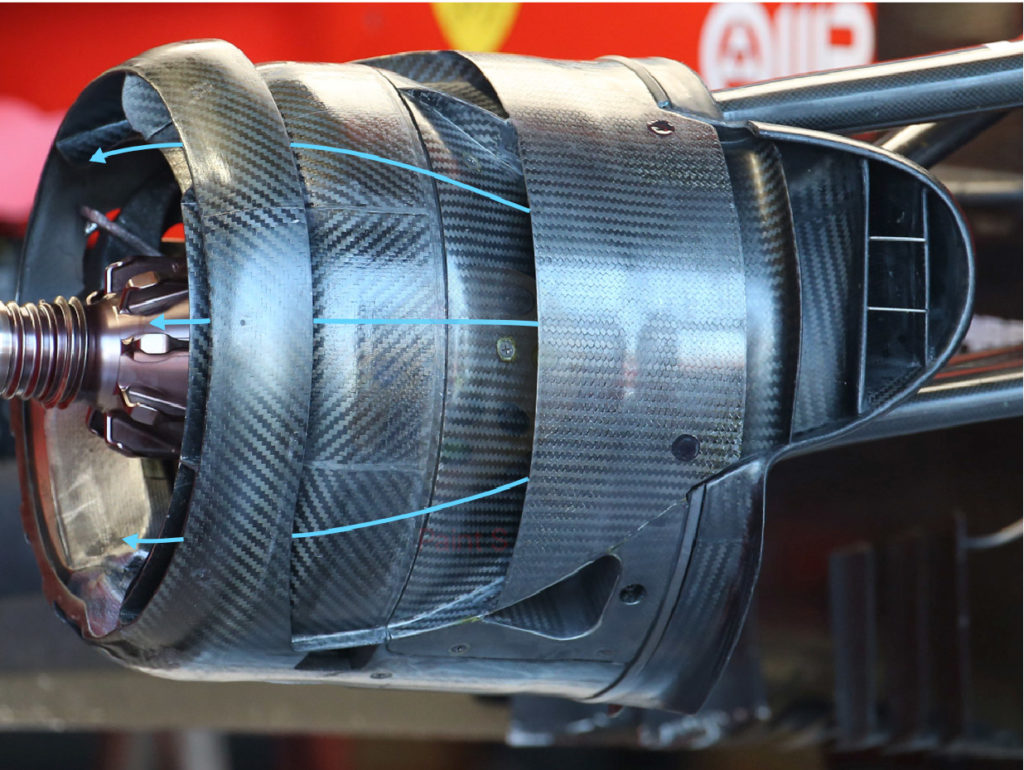

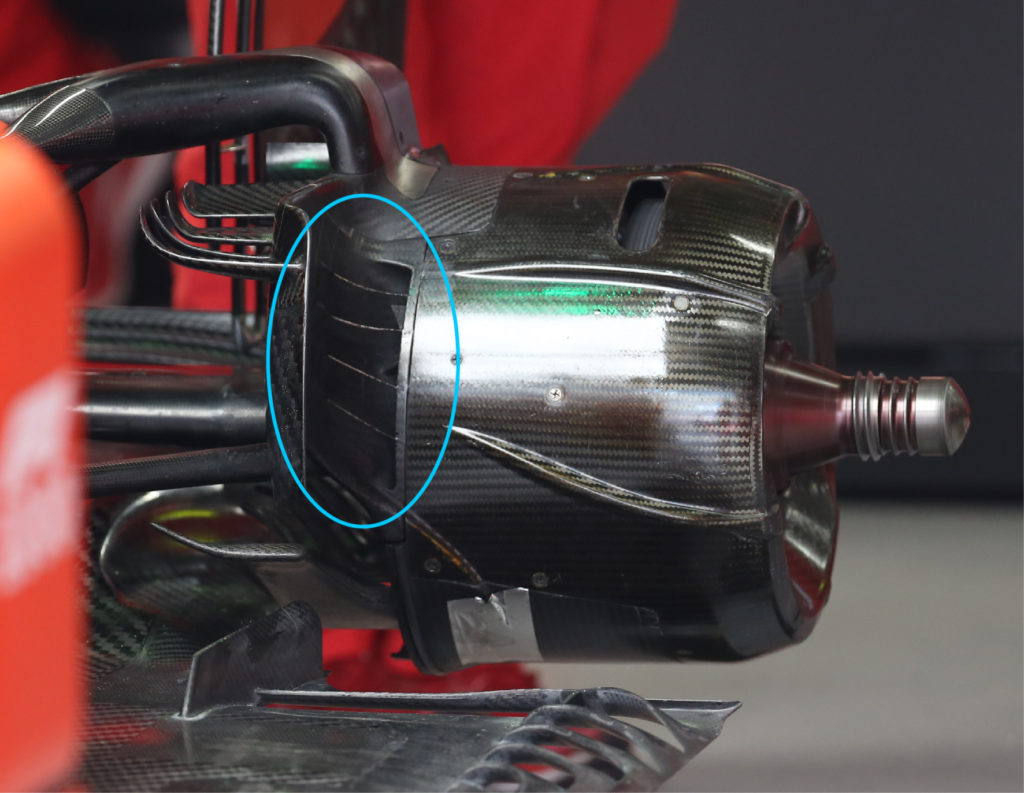

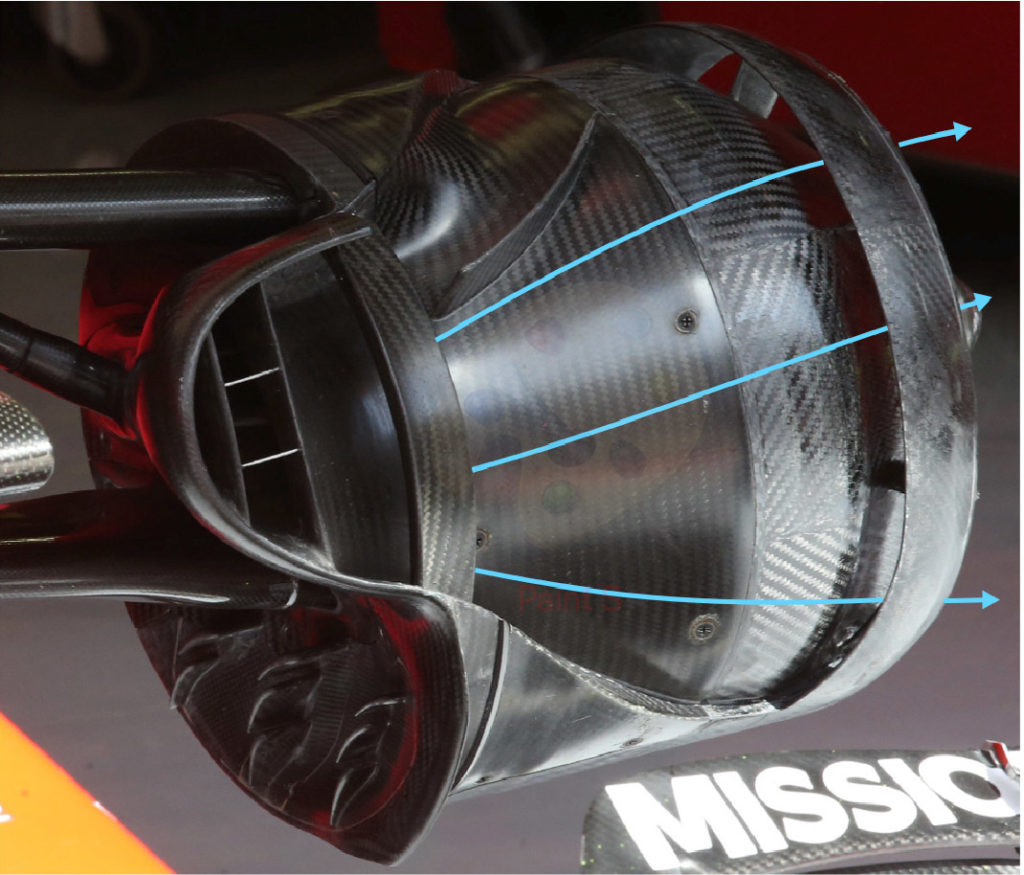

Although this Ferrari front wheel assembly hasn’t changed since the Australian GP, some more detailed shots were taken at the Bahrain GP, allowing us to understand more accurately how Ferrari have manipulated the airflow through the wheel.

Air is ducted to flow across the width of the wheel and then exits through gaps in an outer ring. F1 teams want to maximise the amount of air flowing through the wheel hub to not only cool the brake assembly, but utilise that hot air to increase rim temperature. By channeling hot air from the brake ducts in a thin layer, across the width of the wheel, rim temperature will increase which in turn will contribute to higher tyre temperatures.

Furthermore, this strategy also helps to manage the wake from the front wing. Once the air has flowed over the front wing, it has been ‘worked’ which means it is low velocity and so it becomes turbulent. To avoid this airflow reaching and affecting the efficiency of other aerodynamic devices downstream, teams flow air through the front wheel, which then helps to guide the wake from the front wing away from the car.

This is clearly evident in the front wheel assembly of the Ferrari SF90. Air is ducted through the front brake duct and is guided through an outlet and then travels across the width of the wheel (as shown by the blue arrows). The air then exits the wheel assembly through gaps in an outer ring.