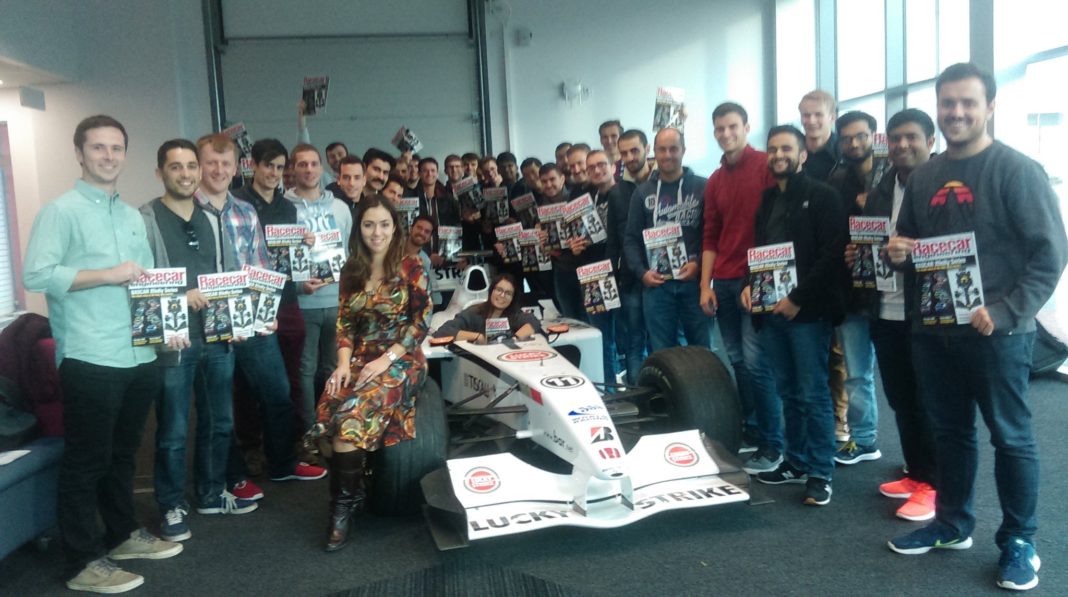

The next generation of Motorsport Engineers begin their Advanced Motorsport Engineering MSc Masters at Cranfield University.

Ryan and Jose from this year’s cohort debrief us on the first few weeks.

Week 1

As we settle down in our new environment we look back and realise how time actually flies. It is a blur! Leaving the comfort of home to study abroad for a year involves a lot of preparation and comes with a degree of anxiety. However, the excitement of receiving our Cranfield University acceptance letters, helped us all through these changes and we couldn’t wait to start!

With students from all corners of the globe, including Italy, France, Spain, Malta, Australia, South Africa and of course the UK, Cranfield’s MSc Advanced Motorsport Engineering course is indeed a dream come true for our entire class of Motorsport enthusiasts. We have worked hard to be selected to join a unique University that is part of the UK’s Motorsport Valley and the epicentre of motorsport!

On our first day we were greeted by Clive Temple, Director of the Advanced Motorsport Engineering MSc and a competitive race driver himself! He demonstrated a deep fondness for both historic racing and modern competition, giving us an in-depth lecture on the evolution of various racing categories, not solely in top level racing such as F1, but throughout motorsport. Today’s racing cars are built on the fundamental principles established by previous generations. It is clear that Clive also has a passion for racing motorcycles and we found out that he also has a number of race bikes!

During the first week we also met the other lecturers who briefed us on the course structure, including how the thesis dissertation works, and how assessment and feedback is undertaken. The Group Design Project is one of the most anticipated segments of the MSc, but Clive and the team would not reveal what we will be working on until February.

On our second day, we were divided into teams and given a practical challenge to help ‘break the ice’ with our peers in the cohort. We were tasked with building a lightweight model chassis with sufficient torsional stiffness and were only allowed to use some spaghetti pasta, a piece of paper and a hot glue gun. The task sounded simple – until we started it. We had very little time to complete the challenge which is lesson number one of Motorsport that we will have to get used to – deliver and deliver on time.

Week 2

The second week was the introduction week, during which we had talks and presentations from experienced professionals in the motorsport industry. Within these talks there was also a lot of interaction, Q&A sessions and discussions which gave us a real insight into the fascinating industry of racing.

For example, Mike Pilbeam told us interesting anecdotes from his past with BRM, Lotus and Surtees. More importantly he gave us plenty of technical advice, emphasizing the main points that make a car win races. Moreover, Stefan Strahnz explained how Mercedes-AMG Petronas Motosport, whom he works for, is organised at Brackley and the team’s philosophy. At the end of his talk, we had the privilege of seeing some real Mercedes components from this year’s Formula 1 car. We never imagined that a senior member of staff from a five time Formula 1 World Championship winning team would visit Cranfield in the second week of our Master’s!

Furthermore, the visit of alumna Gemma Hatton, Deputy Editor of Racecar Engineering, was very useful as we learnt how to get the most out of our year at Cranfield. Undoubtedly, knowing the perspective of someone who has already undertaken the MSc was very informative. The visit of Nigel Jones of the MSA also reinforced what our teaching team had already stated on several occasions: “Motorsport engineers work in relation to regulations which they have interpreted to seek competitive advantage within the rules”.

During the introduction week, we also got to visit Cranfield’s impressive facilities such as the sustained g-cueing simulator. Discovering the advanced technology behind a top level Motorsport simulator in the new IMEC building was fascinating. We also spent some time learning how Finite Element Analysis (FEA) is used in Motorsport and also got our chance to analyse static and dynamic simulations through using LS-Dyna software. It is amazing how CAE programmes enable a high degree of precision to be achieved, even if several details remain unknown. This helped us to prepare for our next challenge: our first assessed module in Motorsport Structures Analysis.

Week 3

Structures week, was when we really started to get ‘hands on’ experience. “You must challenge and question why components fail in a certain way, or act in a certain way. How would you improve them?” This is how our module leader Dr Rishi Abhyankar got us involved, asking us how we would approach a given problem to find a solution. We had to perform analysis of steel tubes being crushed under both quasi static as well as dynamic loads. What really struck us was how the steel tubes deformed under these loads. The amount of energy absorption varies considerably depending on the different types of loading. One of the questions put to us was “Why do F1 car components such as nose cones go through much lower speed impact tests when the cars crash into barriers at speeds in excess of over 150mph?”

We were able to learn first-hand because on the Tuesday Dr James Watson gave us an overview of the Cranfield Impact Centre (CIC); one of only two FIA approved centres for crash tests in the UK. Currently six Formula 1 teams use the Cranfield facility. Access to such a facility and the knowledge of the staff working there gives Cranfield students a real advantage. No other university in the world has such a facility that is so critical to motorsport.

We simulated a situation of a sled impacting an FIA regulated nosecone using LS-DYNA. Top tier racing series teams increasingly add more in-house simulation tests before going to the official impact centre where an adjudicator from the FIA will clear the car to be safe, following successful testing. Any failures mean the teams have to go back and improve their design and its manufacture. The insight we have obtained throughout this module has made us appreciate the design criteria of key components. The structures, their dimensions and the way in which they are manufactured results in reliable components designed to withstand loads to ensure safety.

Relentless and tenacity are two common words used in the fascinating world of motorsport. It is clear this MSc course has these terms in mind. The Cranfield Master’s runs at a pace that will help us transition from students to engineers working in motorsport. We are now part of a global network of motorsport practitioners. Our education will help us become better engineers. Undoubtedly, Cranfield is the right place to achieve this. Pedal to the metal is our mantra…

Written by Jose Aranda (left) & Ryan Vella (right)