Sponsored content in association with

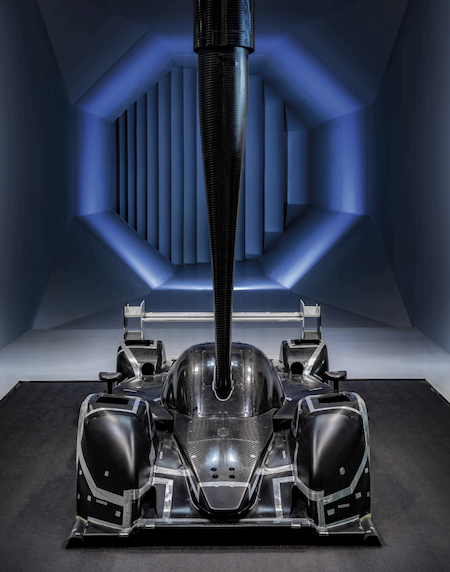

London based Peer Group plc has announced that they are offering for sale its state-of-the-art moving road wind tunnel facility that in 2024 has been substantially upgraded to meet the very latest motorsport and automotive aerodynamic testing needs.

This 50 per cent wind tunnel features an array of advanced capabilities, has been proven to deliver exceptional aerodynamic correlation with track / road and has demonstrated major race car championship winning credentials. Its key differentiator is airflow quality, underpinned by extremely low and consistent turbulence levels, which enable superior test results in comparison to most other wind tunnels worldwide.

The facility, currently located in Huntingdon, UK, was designed, built and continually developed by Lola Cars International Limited, the famous race car manufacturer.

Lola originally acquired the wind tunnel from British Aerospace, re-locating and substantially re-designing it to create an advanced motorsport and automotive aerodynamic testing facility.

Opening in 1998, it quickly became a central part of Lola’s in-house research and development processes, whilst also providing aerodynamic test services to other race car teams, several Formula 1 teams and automotive OEMs.

Since its inception, the Lola wind tunnel facility has been owned by Peer Group plc, or one of its subsidiaries. Peer Group and Lola Cars International were both founded by the late Martin Birrane, Lola’s owner from 1997 to 2021.

Peer Group is now offering the tunnel facility for sale following a 3-year lease to the new Lola Cars business which was formed in 2021 following its purchase of the Lola name and IP from Peer Group.

‘For race car manufacturers, race teams, automotive OEMs and for businesses providing motorsport and automotive engineering services, this opportunity represents incredible value in relation to the cost of building and developing a new wind tunnel, especially as its modular steel construction makes it ideal for relocation to wherever a buyer wishes,’ said Howard Dawson, Peer Group’s managing director.

‘The 2024 major upgrade to the tunnel’s systems now provides for pre-programmed automated testing with full model motion control and easy integration with the very latest sensor technologies, all controlled by Cosworth’s Diablo software which was specifically designed for advanced wind tunnel applications.

‘Project managed by Lola Cars, which since 2021 has been under the ownership of Till Bechtolsheimer, we’ve basically taken what was already one of the best 50% scale motorsport wind tunnels worldwide and brought it up to date with the latest standards of race and road vehicle aerodynamic testing.’

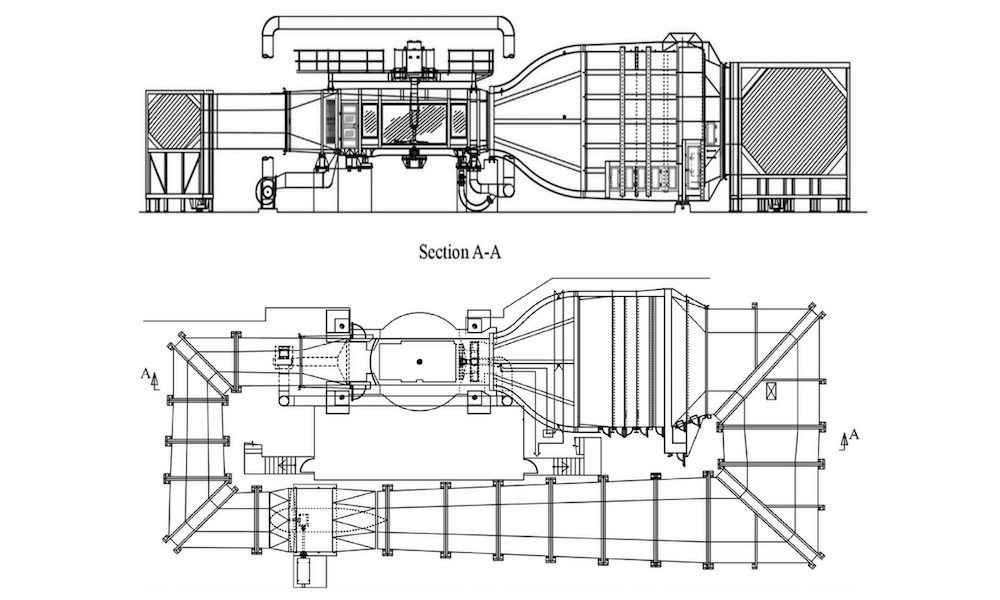

The facility includes an array of supporting workshops, tooling and equipment, including a 7-post chassis rig. The wind tunnel is of steel modular construction allowing for easy relocation worldwide.

David McRobert, who is handling the sale on behalf of Peer Group plc, said: ‘We expect interest from organisations around the world. For some, a UK facility may not be practical, so we’re offering the option of a ‘tunnel only’ purchase, allowing it to be relocated worldwide.’

Wind tunnel details

Flow Quality

The test section accommodates up to 50 per cent scale race car models for maximum accuracy. A combination of flow conditioning screens and high contraction ratio were specified to ensure excellent turbulence and boundary layer control for a tunnel of this size and type, yielding superior quality, accuracy and repeatability of results.

Air Management

The tunnel’s high top wind speed delivers test results with excellent correlation to full size performance. Heat generated by the main fan is dissipated through a large heat exchanger positioned in the air stream and a 520kW chiller unit, preventing temperature build-up and hot spots.

Environmental

The tunnel was designed to provide an extremely low noise signature as required for 24/7 testing.

Balance System

A 6-component overhead balance system manufactured by aerodynamic equipment specialists Aerotech is at the heart of the wind tunnel’s data gathering system. It facilitates precise measurement of lift, drag and lateral forces, along with their associated moments of yaw, roll and pitch.

The overhead balance is mounted on an independent pile foundation to eliminate the influence of external vibrations. Accuracy is maintained by a self correcting calibration system.

Model Control

Hydraulic control of the model’s attitude is fully computerised, enabling constant model motion during runs including yaw and roll plus front wheel steering up to plus ± 10 degrees. A unique feature of the system is the ability to change wheelbase and track from the control room, increasing productivity and flexibility.

Rolling Road Control

The entire rolling road section can be yawed with, or separately from, the model to simulate the aerodynamic effects of slip angles and crosswinds. This data is especially useful for vehicles with less downforce and / or more frontal area (i.e. road cars or EVs).

Computer system

The wind tunnel is controlled by the latest Cosworth Diablo software which was originally designed specifically for complex wind tunnel applications.

Diablo provides a high degree of test automation with tests configured in advance, then automatically managed to run through a sequence of test conditions, controlling and coordinating subsystems, whilst collecting the experimental data and logging it to the PC storage. Data can be analysed while the test proceeds, and performance metrics written into a SQL database. Computer hardware was renewed in 2024.

Facility detail

The 985 sq.m (10,600 sq.ft.) building is of standard industrial building steel frame clad construction and is spread over three floors.

The wind tunnel sits within the facility on separate concrete foundations designed to eliminate movement and vibration. It was designed by Lola to be a stand-alone vehicle research and development facility.

The ground floor contains various workshop areas and access to the wind tunnel rolling road. It also includes a workshop housing a valuable seven-post chassis rig, designed to test and develop vehicle structures and dynamics. This can run a full range of road and race chassis simulations, including use of aerodynamic load data generated during wind tunnel testing. The rig has not been used for several years and requires recommissioning.

The first floor contains the wind tunnel working section and the wind tunnel control room plus a large workshop and tooling for wind tunnel model manufacture and modification. There is also a large lift for transporting test models and equipment from the ground floor.

THE FACILITY IS BEING OFFERED FOR SALE WITH A GUIDE PRICE OF £2.5 M + VAT.

FOR FURTHER INFORMATION, PLEASE CONTACT DAVID MCROBERT – D.MCROBERT@FLYFIVE.CO.UK

07552 012755 (UK) OR + 44 7552 012755 (INTERNATIONAL)