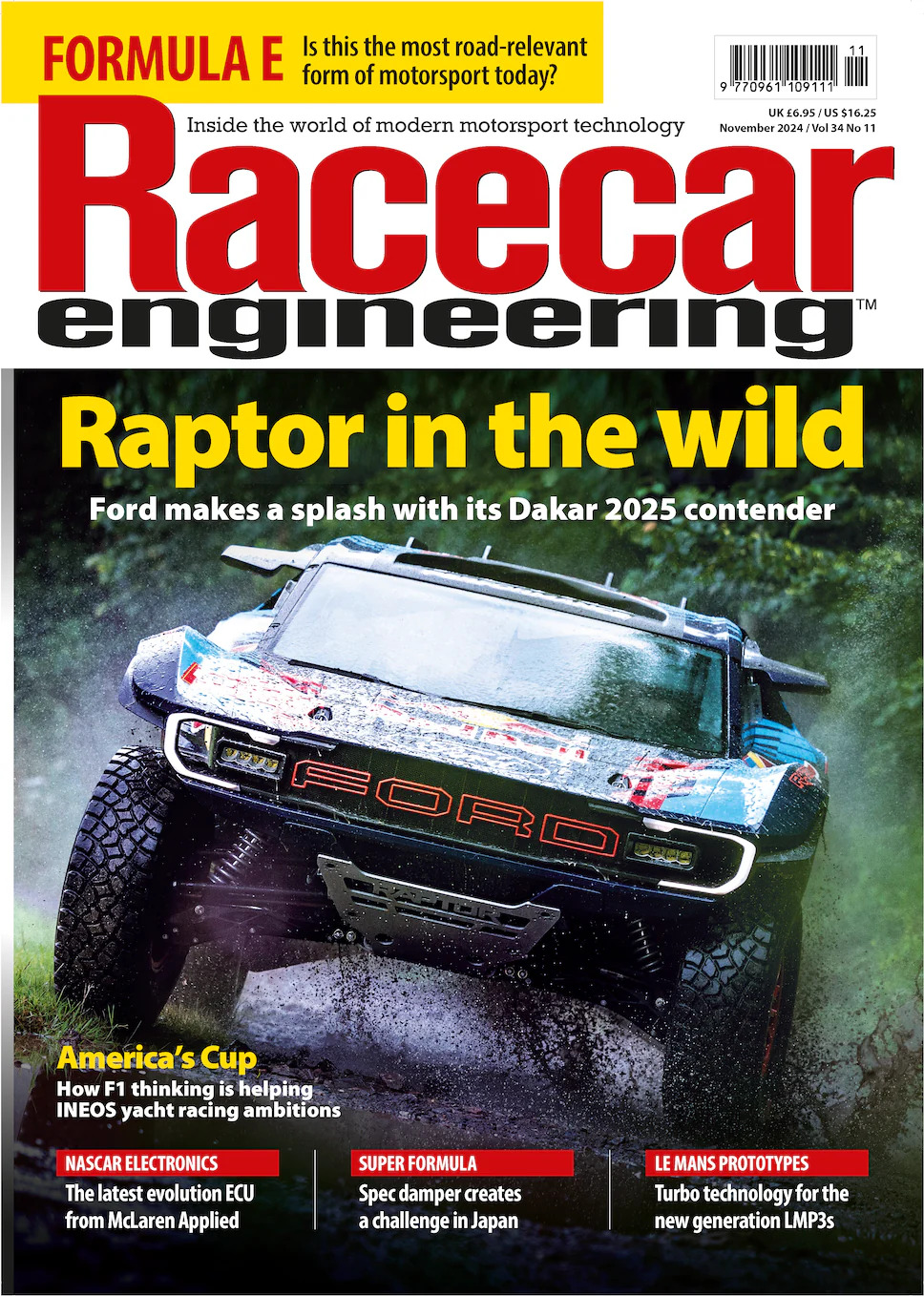

The all-electric Ford SuperVan 4.2 has had a record-breaking 12 months, to say the least. Last summer, with Romain Dumas at the helm, it took on Pikes Peak International Hill Climb in the Open category. Despite some issues during the test runs, the modified Transit van completed the 12.5-mile (20.1km) mountainous climb in under nine minutes, smashing the previous class record by 37 seconds.

In February this year, the van conquered Mount Panorama in Australia, breaking three lap records (fastest electric vehicle, fastest commercial vehicle and fastest closed-wheel vehicle) with a 1m56.32s lap time. Next, it raced to the top of Goodwood’s famous hillclimb course in 43.98s, winning the 2024 Festival of Speed shootout by over two seconds.

So how has Ford transformed its Pro E-Transit Custom van into a 2000bhp+ hillclimb monster?

Ford has been developing its SuperVan promotional vehicle concept since 1971. The first iteration, SuperVan 1, was a crude affair, combining a Ford GT40 chassis and its mid-mounted, 5.0-litre Ford V8 engine, with the factory steel bodywork of a Mk1 Transit van.

In 1984, SuperVan 2 came along, this time built using the chassis from a Ford C100 Group C car and a Cosworth DFL engine, all hidden under a glass fibre representation of a Mk2 Transit, with added aerodynamic enhancements.

A decade later, to promote the Mk3 Transit, SuperVan 2 was converted into SuperVan 3, this time using a 3.5-litre Cosworth HB V8 and a reduced scale silhouette body.

2022 then marked a new era in SuperVan history, with the first electric version, the Ford Pro Electric SuperVan 4.0, unveiled at Goodwood. Ford Performance collaborated with Austrian electric racing specialist, STARD, to deliver a 2000+bhp powertrain capable of accelerating the E-Transit Custom-inspired SuperVan from 0 to 100km/h (62mph) in under two seconds. This one stretched the likeness to a regular Transit van to nominal, at best.

Following the success of SuperVan 4.0 at Goodwood, Ford wanted to face the ultimate hillclimb test: Pikes Peak, but this was to prove a whole new challenge.

Pikes Peak is arguably the most fascinating race event for drivers and engineers alike. The start line sits 2800m above sea level with ambient temperatures typically around 20degC. The twisty, mountainous, 20km circuit winds its way up the highest summit of the southern Front Range of Colorado’s Rocky Mountains to a peak 4300m above sea level, where temperatures are near zero.

At this altitude, the density of air is only 0.72kg/m³, compared to 1.2kg/m³ at the start line. This not only reduces the aerodynamic forces acting on the car, but also the available cooling as well. Consequently, SuperVan 4.0 needed to be re-designed if it was going to top the timings, paving the way for SuperVan 4.2.

Unsurprisingly, a Transit van is not the optimal size, shape or weight for setting record breaking lap times, on any circuit or track. To compensate for this, the powertrain needed to maximise power output and the aerodynamics needed to squeeze every ounce out of the available downforce.

‘The powertrain and the aerodynamics package are the main factors that compensate for the huge mass, frontal area and all the other disadvantages of choosing a Transit as a base package,’ says Michael Sakowicz, CEO at STARD. ‘That’s why we worked so hard to design a compact package that delivered high power density.

‘I’m not aware of many other BEVs that achieve such a high power output for such a small battery, so we’re pretty proud of that. This, together with the aero kit developed by Ford Performance, who did a great job, is how we’ve managed to achieve such impressive records with a van.’

At the heart of SuperVan 4.2’s powertrain lies a bespoke, 50kWh battery made up of ultra-high performance lithium polymer (Li-Polymer) NMC (nickel manganese cobalt) pouch cells housed in a carbon fibre case. To help the battery operate within its optimum temperature window, particularly with the low density air at the top of Pikes Peak, cooling was a priority from the start.

‘The battery is liquid cooled with an oil-based fluid that runs in a separate cooling circuit,’ continues Sakowicz. ‘Cooling is very challenging for Pikes Peak because of the thin air, but I would say 50 per cent of a good cooling system is determined by the layout you choose.

‘The layout of the battery, motors and inverters, as well as how these units are packaged together, is very important. They must match the desired voltage range, as well as the continuous and peak power performance, and then those parameters can be tuned for each specific use case.’

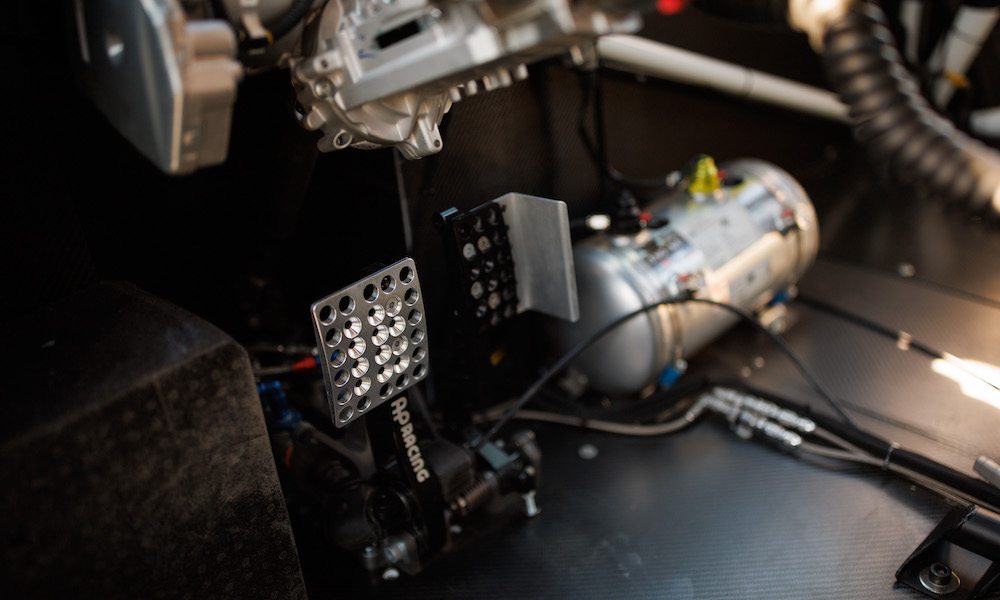

The battery provides power to four six-phase motors, with two on the front axle and two on the rear, each capable of a peak power of 400kW. The front and rear axles are not mechanically connected, but instead have a conventional motorsport differential with a two-stage, single-speed gear. The torque is not distributed between the front and rear axles, but is controlled across each axle by a vehicle control unit (VCU) with STARD- developed software.

Interestingly, the power-to-weight ratio of the powertrain can be specifically optimised for each event by adjusting the number of motors in operation. For Pikes Peak, SuperVan 4.2 only used one of the front motors, for a total of three, while at Goodwood and other events, STARD opted for the full complement of four.

‘Because SuperVan 4.2 was primarily designed for Pikes Peak, its high downforce aero package means we are producing much more downforce at lower speeds [at Goodwood],’ notes Sakowicz. ‘This, combined with the four-motor set up, gives us a huge amount of torque at the front. In fact, we’re actually running a very long ratio because we have so much front torque available that we can achieve a straight line of torque until top speed. Whereas for the rear we use mixed ratios because, in this set up, we have a lot more traction due to the dynamic shift from the axle loads.’

The inverters are IGBT (Insulated Gate Bipolar Transistor) technology and share the same cooling circuit as the motors.

‘We developed the motors and inverters together with a specialist partner, which are cooled with a water glycol fluid,’ continues Sakowicz. ‘We also integrated rotor cooling, so both the rotor and stator of the motors are cooled as well.

‘The battery, motor and inverter cooling circuits all use air-to-fluid radiators. So, located at the front of the car is the cooling radiator for the battery, with the radiator for the motor and inverter circuit behind, as this operates at a higher temperature.’

To generate enough grip all the way up the perilous climb, the aerodynamics package needs to produce as much downforce as possible. Of course, with downforce also comes drag. This is less of an issue towards the top of Pikes Peak as the thin air results in lower drag, but at the start line where the air density is more typical, a great deal of energy is required to overcome the high drag of the high downforce package and accelerate the SuperVan. This was another reason why the powertrain needed to have such a high power density.

‘We are running close to Formula 1 levels of downforce, but with a 1700kg vehicle, compared to the minimum weight of an F1 car, which is 796kg,’ highlights Sakowicz. ‘More than 50 per cent of that downforce is on the front axle, and at sea level at 200km/h [124mph] we have about 2200kg of downforce in total.’

The upgraded aerodynamic package features a new carbon fibre front splitter and monster rear wing. Centre ducts in the floor help channel air from the bottom and guide it towards the rear and over the rear axle.

‘The frontal area of this van is around two to three times bigger than a typical GT car, so we had to find ways around that with an efficient aerodynamics package that is very different to other cars,’ explains Sakowicz. ‘This made packaging a challenge, particularly the rear axle, which is extremely tight, as the unit is quite powerful and so needs some space, but the diffuser is located on the bottom with ducting above.

‘Other areas, however, were relatively easy to package due to the van’s large size. For example, because the bonnet is so high, the driver needs to sit higher up to have a clear line of sight, so that lends nicely to locating the battery packs underneath the driver.’

The combination of high downforce, extreme power and significant weight of SuperVan 4.2 generates loads at the wheels that seriously punishes the tyres.

‘We are quite limited by the tyres,’ admits Romain Dumas, five-time Pikes Peak and two-time 24 Hours of Le Mans winner. ‘With the weight and the downforce, we could run with much bigger tyres, but nobody makes them. So we have had to use 18in Pirellis based on GT tyres. We could probably go even faster if we had more bespoke tyres.’

‘It’s not just the tyres that we are pushing to the limits,’ agrees Sakowicz. ‘We are loading the wheels, steering, suspension and brakes much more than any other car. It’s very different to any other vehicle we’ve worked on and has caused us a lot of headaches. We’ve had to adapt systems that have been tested and validated in much lighter, less powerful vehicles and really take them to their limits, so that has been a big challenge as well.’

So, what is this 2000bhp creation like to drive around some of the world’s most exciting circuits?

‘It’s more or less like driving a Dakar car, but with a lot more power and a lot faster,’ says Dumas. ‘The most difficult thing is to drive and brake with the weight because, due to the high centre of gravity, there is quite a lot of roll. Particularly as the battery is underneath you, which is good for weight distribution, but it means you sit quite high, so as soon as you steer there is this rolling response from the weight. Grip from the front axle is very good though, it is just as sharp as a conventional racecar.’

Piloting the SuperVan up Pikes Peak, Mount Panorama and the narrow hill at Goodwood required three very different styles of driving.

‘Goodwood is not at all for this car. It’s far too wide for this hillclimb, so this is probably the event that I was furthest from the limit,’ says Dumas. ‘Bathurst, on the other hand, was where I was pushing the most because we knew the lap time of the [modified GT3] Mercedes that we wanted to beat.

‘I mean firstly, we were never expecting to compete against them because we were expecting to go much slower but, when we saw their time, I was determined to go again.

‘The best thing about the SuperVan, compared to the Mercedes, was our top speed. We were going more than 300km/h [186 mph],’ smiles Dumas. ‘Travelling at that speed, with all the elevation at Bathurst, at the crest was the most challenging in terms of intensity. Particularly as we had some issues with the power steering system because we were so much faster than expected.’

‘Pikes Peak is a different challenge again because you cannot go 100 per cent as you only have one chance,’ continues Dumas. ‘So, even if you do a good run, you know you could improve here or there. It’s very difficult to be on the limit the whole time when you only get one lap.

‘You also have the issues with battery cooling. People have the attitude that electric cars have such an obvious advantage at Pikes Peak because you are not losing performance [from the engine due to the change in altitude]. This is completely true, but people often forget that batteries are heavy and need to be kept cool. So, although you don’t lose power going up the hill, you have to limit the top speed because you are never quite sure if you’re going to finish the run, or if the battery is going to overheat. It was the same with the [Volkswagen] ID.R.

‘At the end of the day, the concept is really fun,’ concludes Dumas. ‘If you strip the car out, it really is a racecar with a tube-frame chassis, wishbones, uprights and everything. But for the marketing side it needs to look like a Transit, which is why it is so big and heavy. It is a bit rustic, I would say. Daniel Ricardo drove it in Melbourne last year and he was a bit scared!’

‘It is incredibly quick,’ concludes Sakowicz. ‘At Goodwood, we’re competing against cars like the Subaru Project Midnight, which is the best you can build on the base of that vehicle. While at Pikes Peak, we smashed the Open class record, and in Bathurst set a closed-wheel vehicle lap record against unrestricted GT3s with Formula 1-style DRS. So we are a lot faster than some incredible racecars – with a van!

‘Overall, we’re really proud of how reliably it works, and also how adaptive it is,’ continues Sakowicz. ‘Normally, these one-off projects are designed for one specific challenge, but SuperVan 4.2 is so versatile that it can achieve phenomenal performance from drag strips to hillclimbs, and even rally stages.’