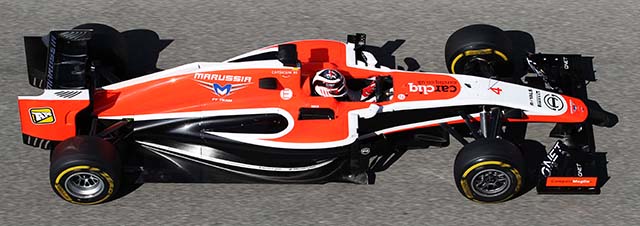

The MR03 was the Marussia F1 Team’s design response to the dramatic and far-reaching technical regulation changes of 2014, the most significant of which was the departure of the normally-aspirated engines which have prevailed in the sport since 1988, in favour of a new, more road-relevant powertrain system, underpinned by a 1.6 litre turbo-charged V6 power-unit. It was an innovate design that should have been replaced at the end of the season with an even more advanced concept but that was not to be.

The process of conceiving the MR03 began in early 2012 when a small 2014-focused design group initiated the very first chassis layouts. 12 months on, as the 2014 Technical Regulations began to take shape, an exciting new powertrain partnership was forged with Scuderia Ferrari and the design process gained greater traction, in parallel with the 2013 Grand Prix season and development of the MR02.

The extent of evolution between the 2013 and 2014 cars can best be characterised by the fact that, of the 11,212 components that made up the MR02, only a handful of assemblies have been carried over to the MR03. The result, as Chief Designer John McQuilliam highlights, is the Team’s “best-ever optimisation of performance versus innovation versus design integrity.”

“Through the course of 2012,” he continues, ”we analysed every single element of the car – from the tip of the nose to the trailing edge of the rear wing – knowing just how radically different the MR03 would be under such sweeping Technical Regulations. We have benefitted enormously from the stability of our design teams, with the same personnel beginning – and now concluding – the process over a 24 month period. I think we can feel justifiably proud of the way we have responded to such a significant challenge and the quality of car we have arrived at with the MR03. The car has been manufactured and finished to a very high standard, whilst achieving our most significant weight-saving targets to date and, importantly, with a crucial eye towards maintaining our excellent record of reliability.

Without doubt, the greatest design challenge has been in terms of cooling, yet this is one of a few areas where we are not only very pleased with the design response, but also the degree of innovation we have achieved with our solution. All-new front and rear suspension layouts are a product of the new aerodynamic regulations placing greater emphasis on mechanical performance, with the mechanical systems now having far greater real road relevance.”

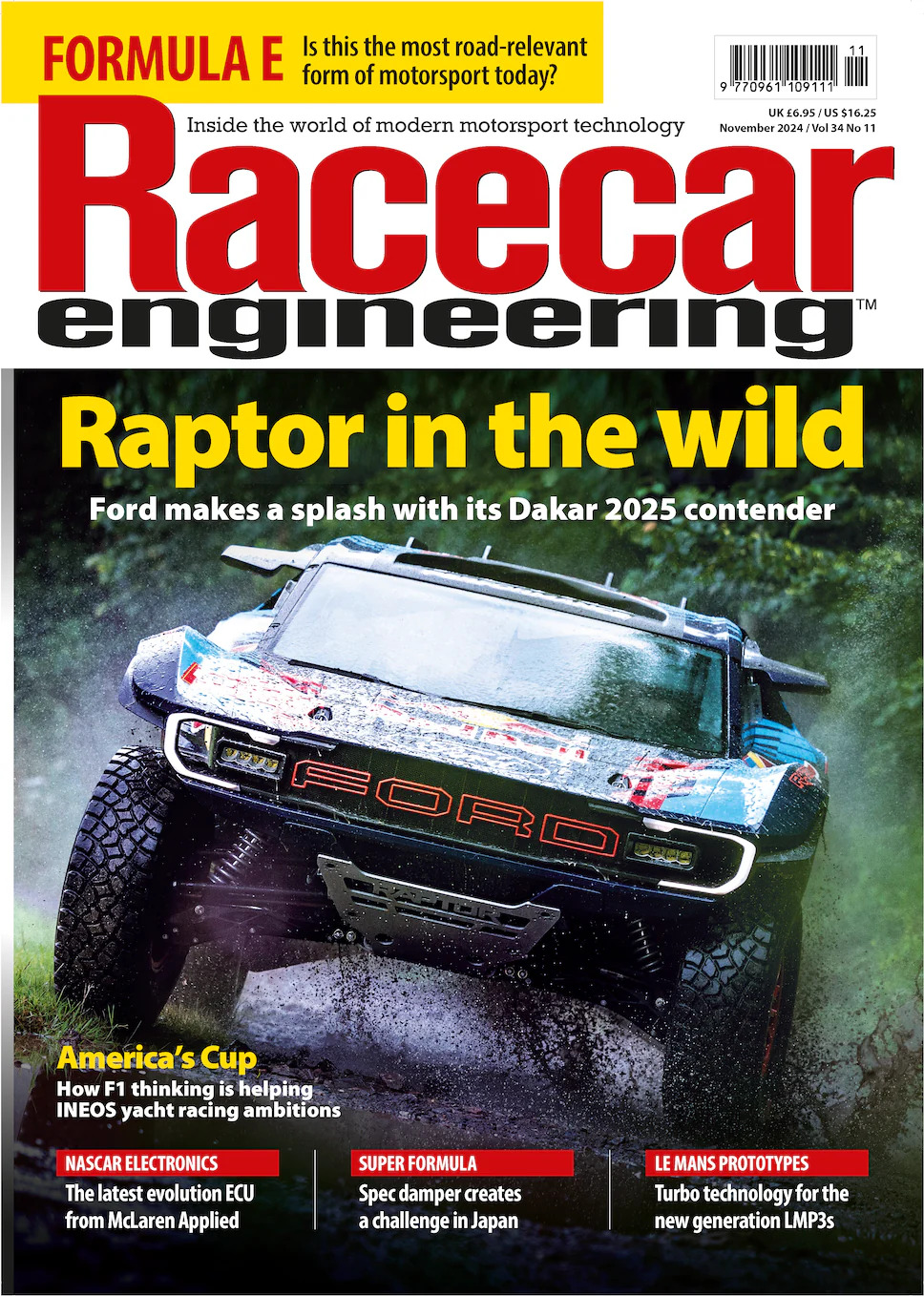

TEST 01: JEREZ, SPAIN

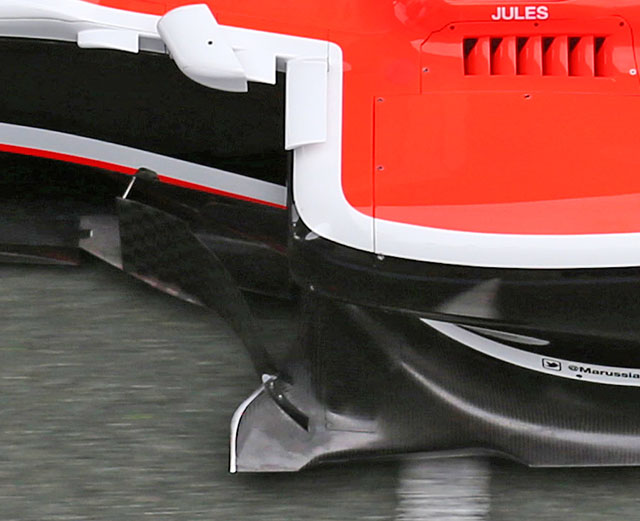

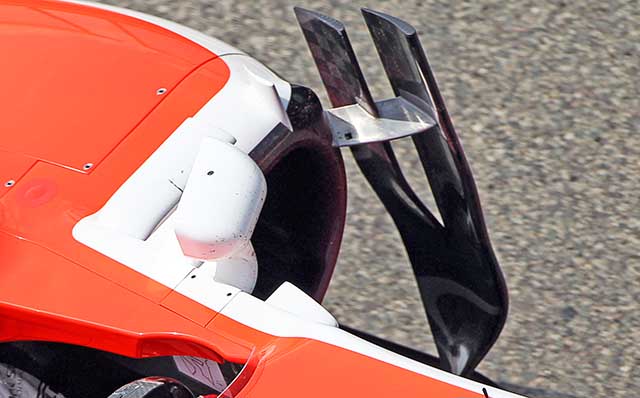

The Marussia MR03 has very few aerodynamic details, but there are some around the cockpit including three turning vanes below the wing mirror. Note also the cooling louvers next to the drivers head protection.

A look at the aerodynamic elements around the front of the side pod. Note the barge board

The nose of the MR03 is thought to be the design that has provoked the FIA’s Technical directive about nose safety. The tip of the impact structure is much larger than its stalk.

Marussia used some of its restricted running at Jerez to do some flow vis running, note the red dye on the front wing, then the spray collecting on the splitter, wing mirror, brake duct and wishbones.

Looking along the side of the car you can see a small bump above the radiator duct, this is likely to accommodate the mandatory side impact structure. The pull rod rear suspension is also clear to see.

The rear wing support is similar to that used on the McLaren, with the single pillar splitting above the tailpipe in what the team call an ‘inverted Y-lon’.

The cooling package on the MR03 is interesting with the car being the only one on the grid without an exposed roll hoop. The air box appears in its usual location, beneath it is an extra cooling duct with a roll hoop support pillar splitting it. Behind the roll hoop there is an additional cooling duct.

TEST 02: SAKHIR, BAHRAIN

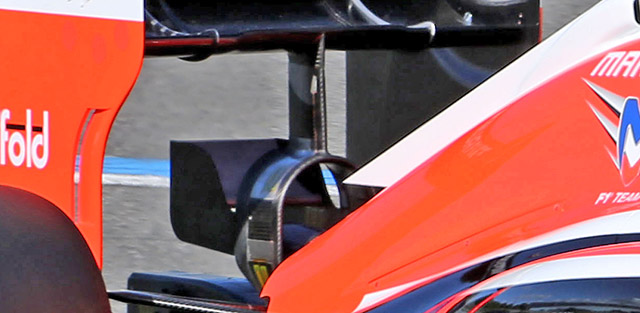

A good look at the side pod turning vane on the MR03. Note the white turning vane on top of the side pod too.

TEST 3: SAKHIR, BAHRAIN

Much of Marussia’s time at Bahrain was spent trying to get the MR03 to run reliably, something that did not work out too well. This has left the team short on mileage ahead of the first race, meaning that it will be something of an achievement for the team to make it to the chequered flag. This will be a shame for Max Chilton who has never failed to finish a Grand Prix (though has also never finished higher than 14th)

A few minor changes were made to the rear of the car including a new coating on the ‘y-lon’ wing support and the ‘monkey seat’ winglet. Seen here as a lighter coloured section. Note the temperature strips.

Despite having a smaller fuel tank and shorter engine packaging the Ferrari 059/3 power unit has meant that the MR03 has a significantly longer wheelbase than the MR02 of 2013, 3700mm compared to 3400mm.

2014 RACE SPECIFICATION

Due to the MR03’s unusual development history we have decided to sum up its 2014 development and specification in one section rather than adopt our usual race by race development approach.

Due to the MR03’s unusual development history we have decided to sum up its 2014 development and specification in one section rather than adopt our usual race by race development approach.

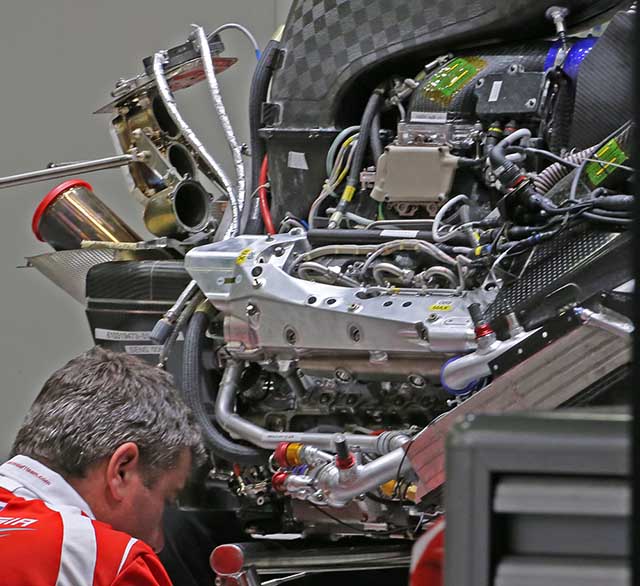

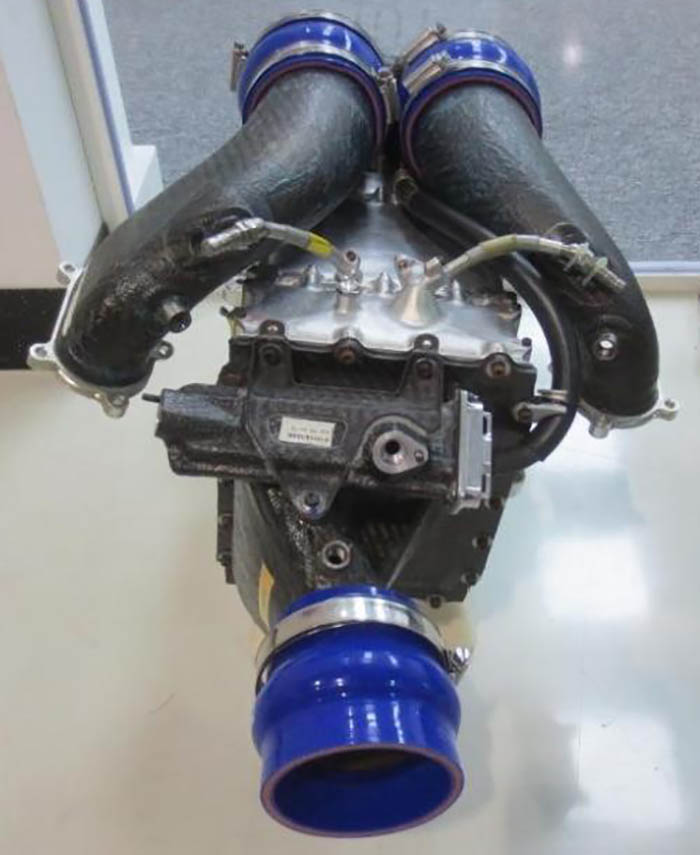

Under the bodywork of the MR03, the installation of the Ferrari 059/3 power unit is clear to see. Just how crowded it is under the engine cover of a 2014 F1 car is evident with the V6 engine barely visible, just the rear of the cylinder head is visible. The air filter though and plenum is clear to see, as is the exhaust system layout with its shielding removed.

With more components removed the Ferrari V6 engine is obvious. The sheer complexity of this new generation of car is incredible and its obvious why it is hard to get them to work correctly. Note the waste gate pipes (sans waste gate)

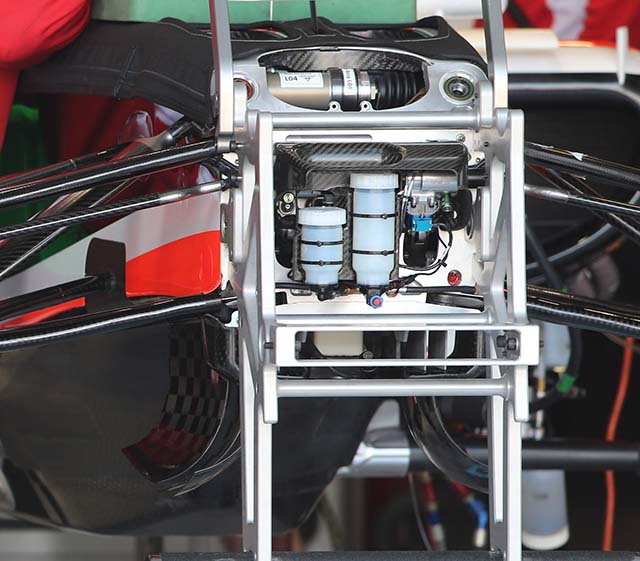

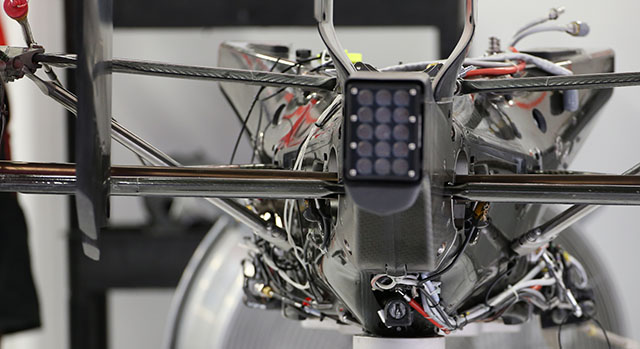

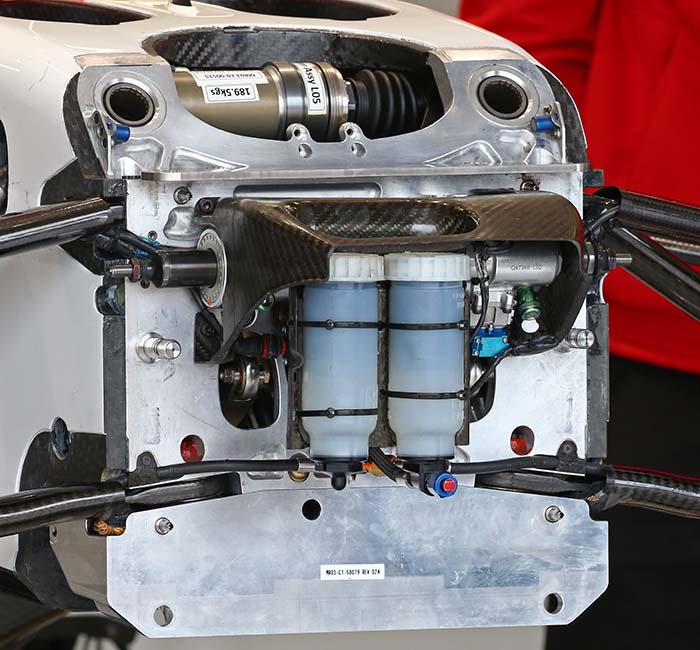

A look at the front of the MR03 shows some detail, including the torsion bar location and the master cylinders. Note also the shape of the base of the tub with a large cooling slot. Uniquely in 2014 and indeed contemporary single seater design the front bulkhead is made from aluminium rather than carbon fibre.

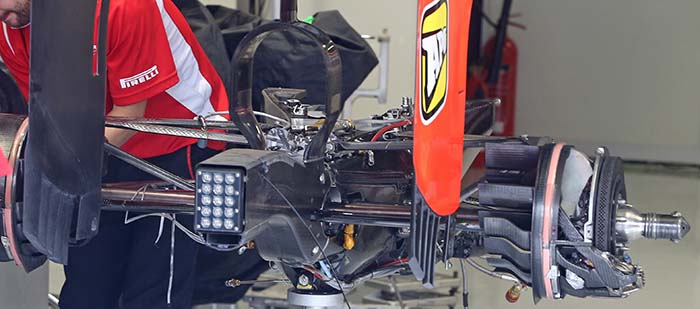

Here we get a look at the inboard suspension pickup points on the Ferrari transmission used by Marussia. Note the base of the y-lon rear wing support on the top of the rear crash structure. Something many teams copied during the season but was pioneered by Marussia.

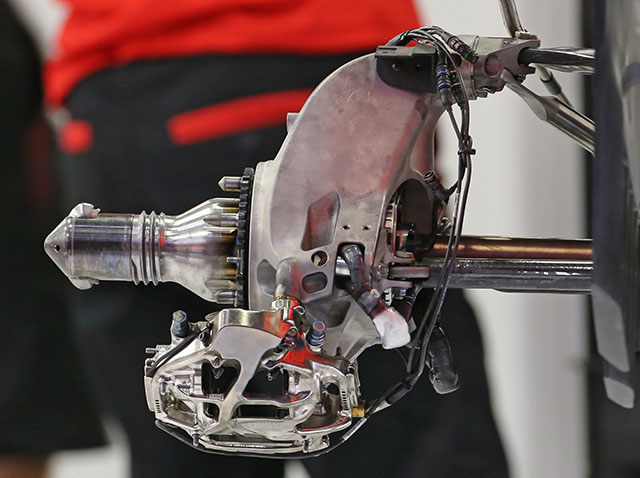

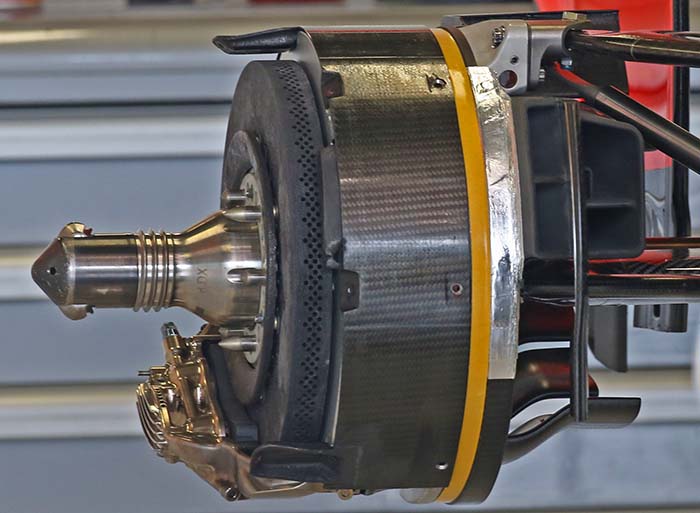

The outboard upper mounting is clear to see from this shot of the MR03’s rear upright. Note the brake caliper design, using a FEA optimised concept popularised by Alcon with OSCA and AP Racing with the Radi-Cal.

With the upright and brake area more built up the design becomes clearer, note the stack of winglets on the inner face – officially these are a ‘brake duct’.

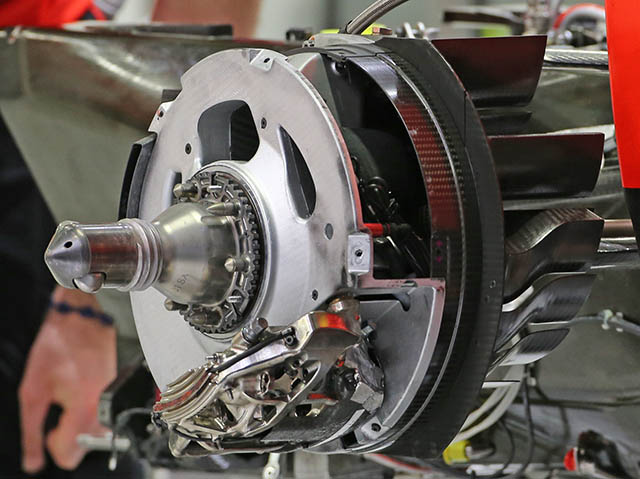

Finally a look at the fully assembled rear brake complete with disc and cooling package.

The front brakes also have a range of aerodynamic elements on the inner face. These not only create downforce acting directly on the wheel but play a more important role on the flow structures in the wheel wake.

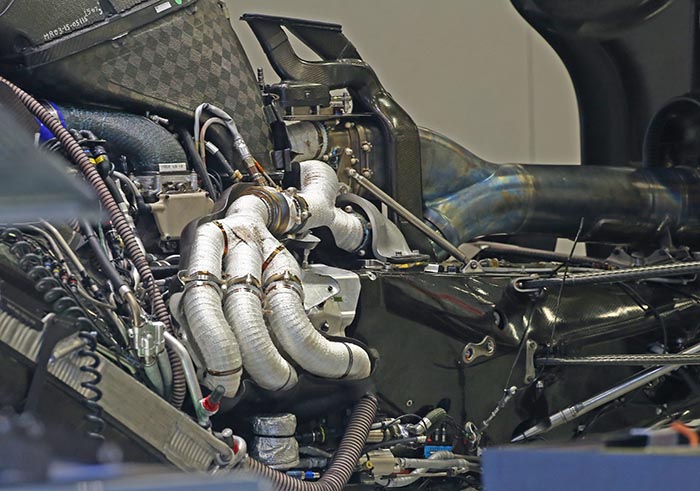

Later in the season the Ferrari V6 engine was upgraded to some extent, and exhaust wrap was added, the absence of which had confounded many engineers at rival engine manufacturers as they felt the lost heat would cost performance overall. Note the turbo cooling pipes fed from the engine cover mounted duct.

A look at the opposite side of the power unit of comparison. The exhaust wrap is clear to see here, as is the pipe arrangement to the waste gate.

A look at the exhausts from the MR03 removed from the V6 engine. Note the 3 into 1 up and over arrangement designed to allow the aerodynamics team to optimise the body work of the 2014 Ferrari.

At the rear of the car the design owes much to Ferrari, the gearbox casing (and internals) and inboard suspension points are all identical to those used by the 2014 Sauber and probably the Ferrari too. Note the brake duct winglet arrangement and the Y-Lon wing support.

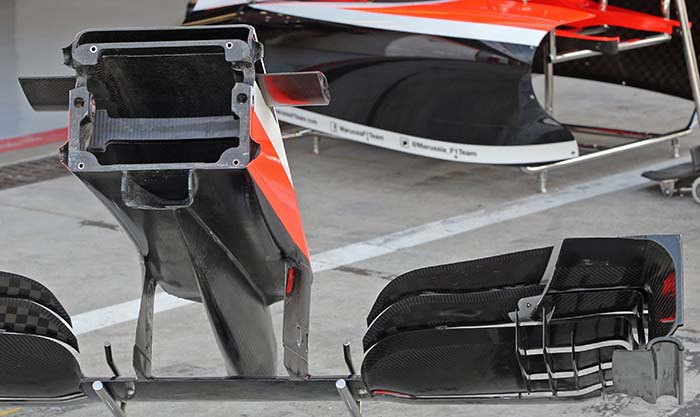

A good look at the inner face of the MR03’s 2014 nose. Note the way the impact structure drops down. The vanity panel at the top of the nose to cover up the ‘hump’ is clear to see. The underside of the front wing is also of interest.

Sadly one of the Marussia MR03’s was written off in a freak accident that almost cost driver Jules Bianchi his life. This revealed that the car had a software conflict which prevented a FIA mandated failsafe system from engaging but it had little influence on the overall result of the crash. See here for more details: JULES BIANCHI CRASH REPORT.

The spare car was prepared to race at the Russian Grand Prix but ultimately the team only fielded a single chassis. As a tribute to the teams driver fighting for his life the car remained in the garage built up and ready to run.

2015 – The updated Marussia MR03

Marussia’s final race was the Russian Grand Prix, after which it collapsed financially and all of its assets were sold off at auction shortly before Christmas 2014. The two remaining 2014 race cars MR03-02 and MR03- 03 were due to be sold off later after Ferrari had removed its assets, the transmissions and engines. The auction was uploaded online and bidding was underway when it was suddenly stopped. A last minute rescue package had been put together.

But Manor as the Marussia team was now known did not have a 2015 car, as some in the paddock especially Force India were at pains to highlight. However the MR03 did in fact largely meet the rules in every respect bar one, the front chassis height and the overall nose shape. The team applied for a dispensation to allow them to run the old nose and apparently this was given, so it was a small surprise when the cars appeared in Melbourne with what at first glance appeared to be cars with 2015 compliant noses.

But on closer inspection it is revealed that while the nose structure, very similar to that seen on the Manor MNR1 design is new, the front of the chassis remains unchanged. Instead a small composite spacer plate has been added between the nose and the chassis. It is just visible below (we hope to get a better image of this soon)

The plate mounts to the front of the tub using the original nose pickup points in the aluminium bulkhead. It appears to have very little difference to the 2014 version beyond a blanking plate being added at the base where there was a cooling slot in ’14.

The space plate adds a little length to the 2015 specification MR03 and this can be seen externally with the distance between the rear of the front wing and the tyres becoming longer.

The exterior of the spacer plate can be seen here with by looking at the panel lines on the car. The forward front wishbone points remain as they were in 2014 but now there is a short extra section ahead of the nose.

The exterior of the spacer plate can be seen here with by looking at the panel lines on the car. The forward front wishbone points remain as they were in 2014 but now there is a short extra section ahead of the nose.

The unusual T-Bar style roll hoop support and cooler arrangement has been retained on the updated MR03 (seen above in 2014) this duct feeds into centrally mounted coolers which allow for the side pod volume to be reduced. The internal layout of this pipe work became apparent when the components of the 2014 MR03 and Manor MNR1 wind tunnel models were sold off at auction. Note the flow conditioners inside the lower duct (above).

The rear of the cooler layout can be seen in the image above, (thanks to @andylaurance for the tunnel model images) while designed in this example for the MNR1 the part is interchangeable with the 2014 version. The upper portion of the duct feeds combustion air rearward to the compressor via the air filter while the lower portion supplies air to the intercooler.

During wing tunnel tests the pressure drop from the intercooler was simulated using interchangeable pieces of wire gauze. Via some unseen arrangement the combustion air was then divided into two and fed to the charge air cooler (below)

With the air from the roll hoop duct apparently entering via the two pipes coiled over the cooler. Looking from the back of the cooler assembly which was mounted at the front of the V6 engine (as can just be seen in some of the other images in this article – it fed air back into the plenum via a single pipe – seen here with what appears to be a piece of Samco sport hose.

Under bodywork little has changed on the MR03’s the 2014 specification Ferrari power unit is present – with its late season exhaust wrap in evidence, as is the 2014 Ferrari transmission.

The use of the 2014 power unit which was not designed to have the life of a 2015 unit could cause the team to accrue a number of penalties but it has yet to complete the design of an installation for the up to date and more powerful unit used by both Ferrari and Sauber.

A look at the side impact structure on the MR03, unchanged from 2014. However the car has been fitted with a larger anti intrusion panel on the side of the chassis.

The brake setup on the MR03 carries over from 2014, this was one of the areas where the car was particularly weak last year. (rears above, fronts below)

The rear of the brake disc wear sensor is visible in the image above, it is the small red part sticking out from the inner face of the disc with a wire running upwards from it. The brake cooling ducts are identical to 2014.

It remains unclear if Manor will introduce the MNR1 at any point, a further update of the MR03 or something else. It will have to do something relatively soon as it no longer has the moulds to make many of its composite parts including crucially the chassis. It also only retains two chassis MR03-02 and MR03-03 meaning that if one tub gets damaged before any new car or design is ready the team cannot replace it.