The Sauber C35 is at first look a mild evolution of the C34, but looking into the details there are some areas of note to observe. The C35 was created under the leadership of Mark Smith who had worked at Caterham previously. His mission was, according to the team’s press kit, to come up with a different approach for the car and team. “For the development of the Sauber C35-Ferrari, we slightly changed the philosophy of how we developed the car aerodynamically. It sounds little, but the impact on the development of the car is significant,” says Mark Smith. “When looking at the Sauber C35, it is very much an evolution,” he adds.

The Ferrari power unit layout has changed significantly from 2015 and that has seen Sauber have to react to that, but also Ferrari’s new transmission casing has allowed the Swiss team to create a car with a tighter rear end..

The sidepods on the C35 (above) are also tighter than those of the C34 (below) according to the team but the ducting seems extremely similar, perhaps the C35 has a slightly smaller duct.

The rear suspension of the C35 is defined by the Ferrari gearbox casing supplied to Sauber by the Italians. This means that it like the Ferrari uses pull rod actuated torsion bars and dampers, they are located in a single block fitted inside the bell housing of the the gearbox

Compare the rear of the sidepod of the C35 (above) to the C34 (below) and it is clear that the new car is indeed a touch tighter.

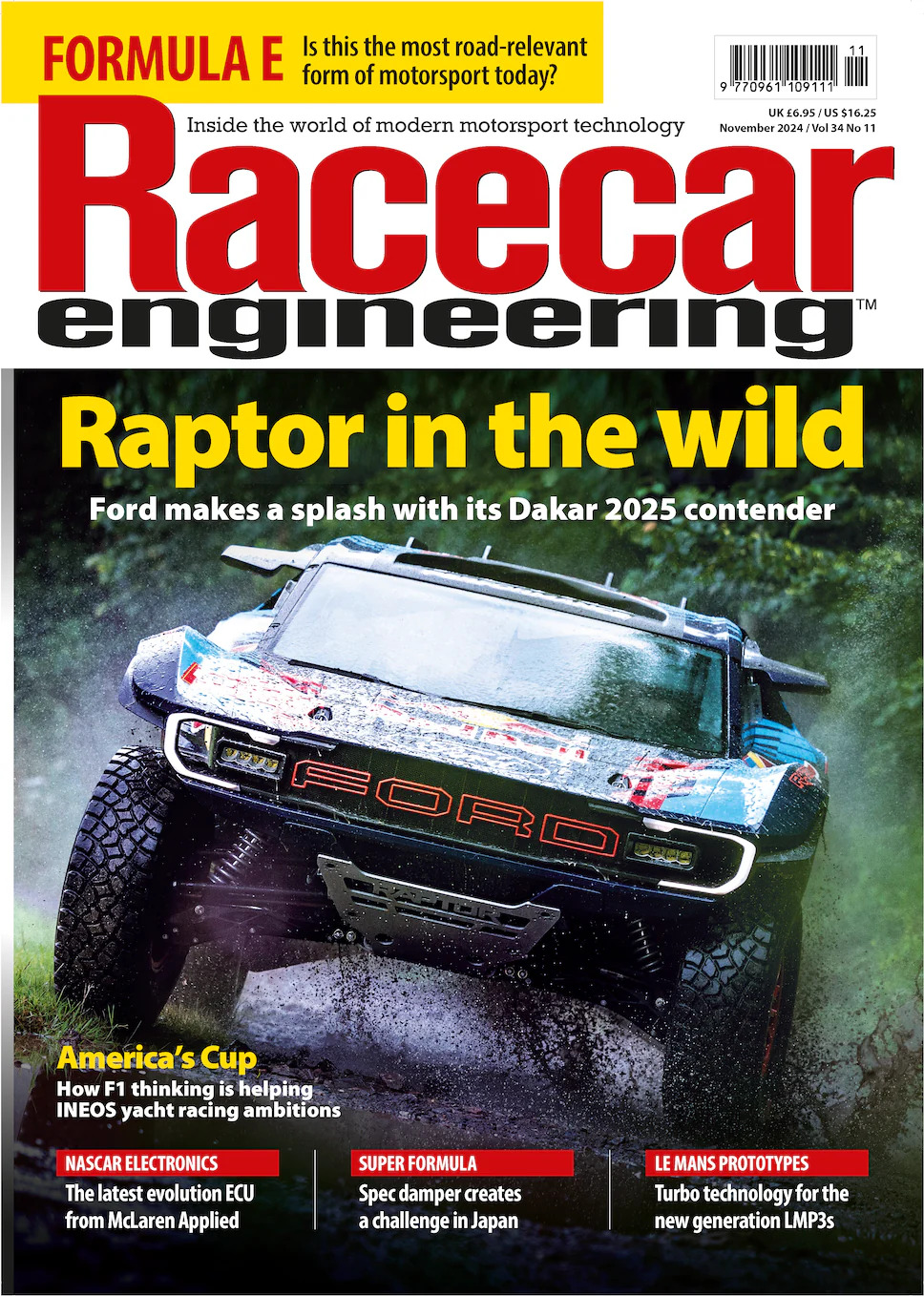

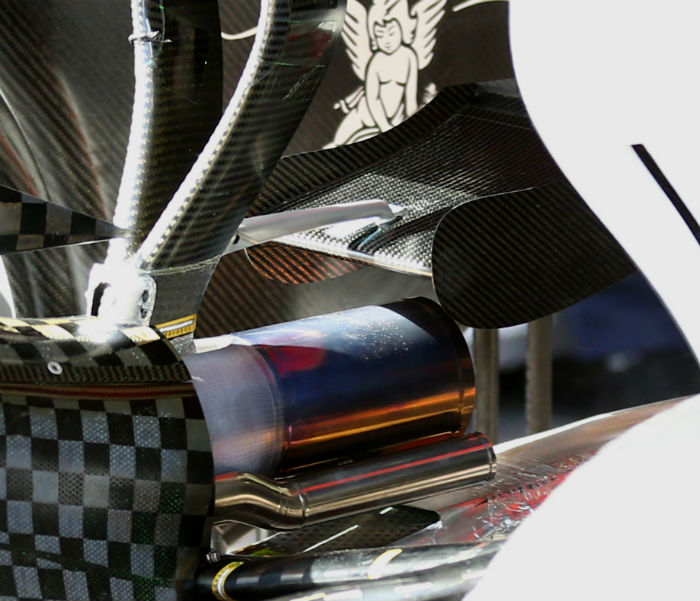

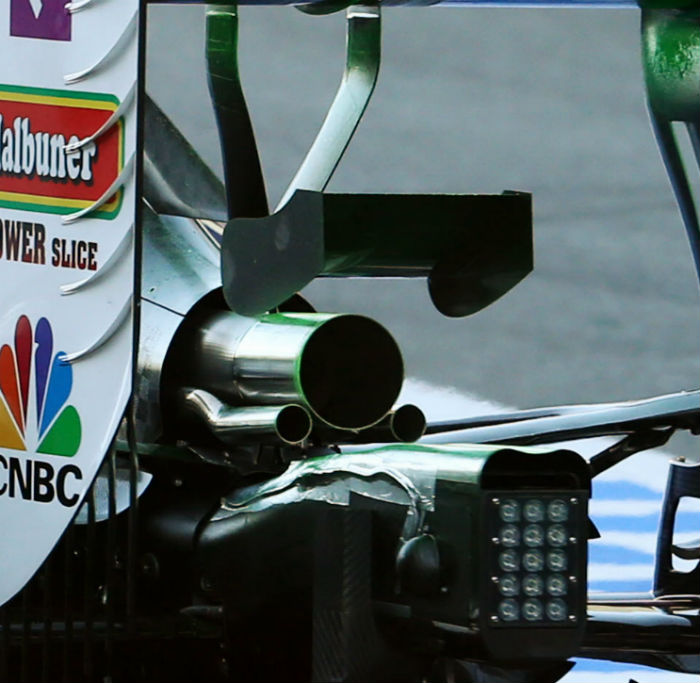

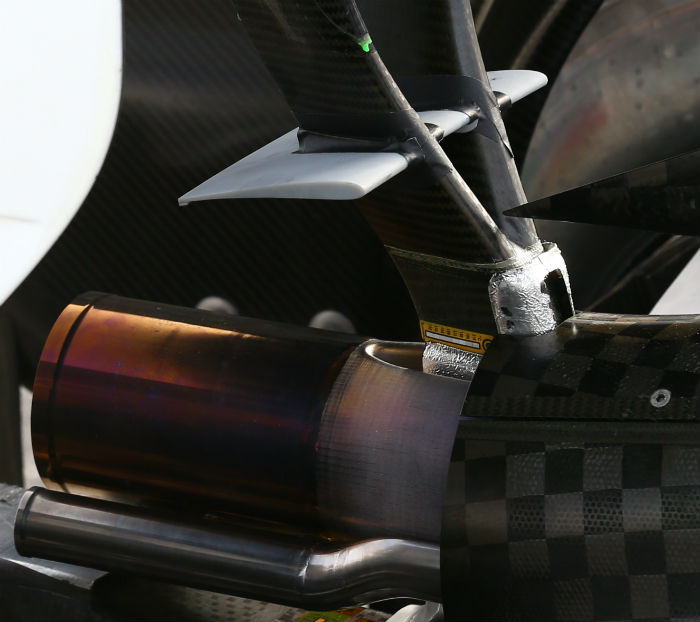

The Sauber tailpipe and rear wing support (below) is of interest, it has a single mounting point on the top of the Ferrari gearbox casing, it passes through the tail pipe and then branches into two as it climbs up to the rear wing itself.

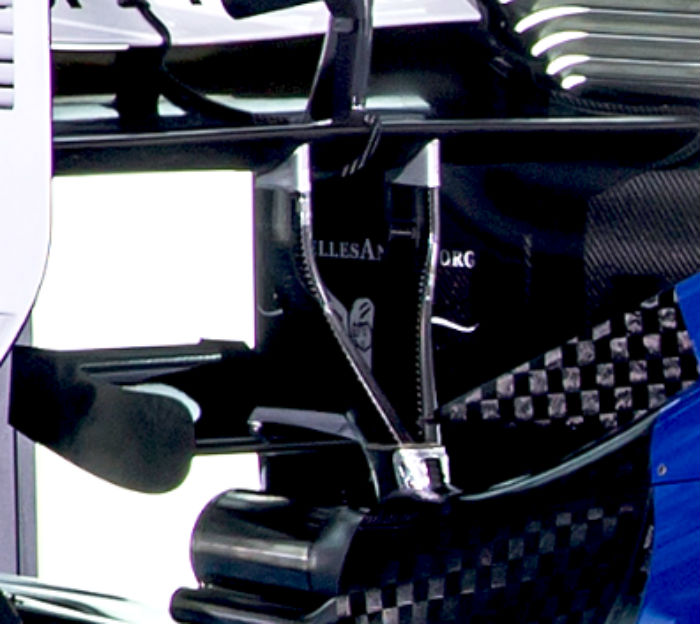

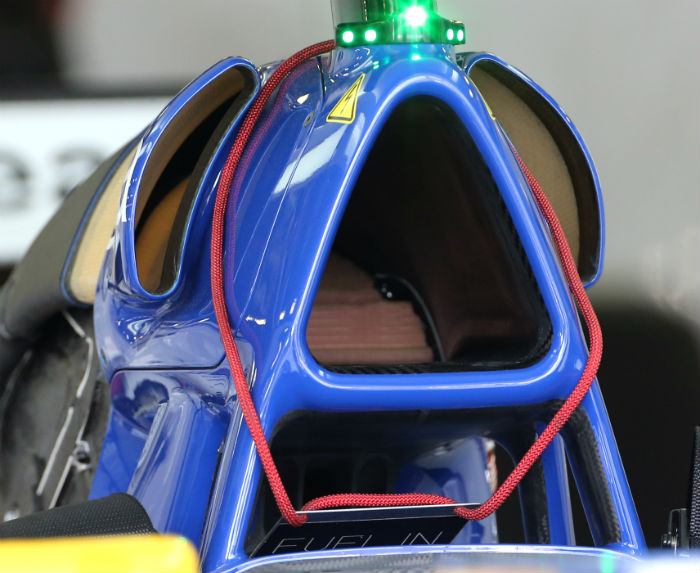

The roll hoop concept of the C35 has carried over entirely from the C34, but the engine cover mounted turbo cooling duct has vanished due to the new layout of the Ferrari V6.

From the front the roots of the concept are clear, note the segmented cooling duct under the main duct a variant of what was seen in 2015.

The C34 featured the same ducting around the roll hoop.

The main triangular duct on the C34 basically carried over from 2014 and feeds the engine combustion air. Beneath it lie two more ducts of unknown purpose, but likely cooling electrical components.

Overall the roll hoop concept of the C34 carries over from the C33, and aside from some blue paint and the ‘ears’ seems to be otherwise identical. Compare the 2015 roll structure (above) with the 2014 (below) and at first glance it is hard to tell them apart. But the 2015 version is a slightly more regular shape and the front legs are narrower.

This is a concept that was brought to Sauber by James Key some years ago after he first tried it out at Force India (below) and the Swiss team has stuck with it ever since

Sauber is still clearly capable of following its own routes in terms of car development too.

The Sauber nose concept has carried over with the protruding front impact structure. Compare the C35 (above) with the C34 (below)

This type of nose also seems to have provided some inspiration to Sauber’s engine and transmission supplier (below)

Sauber’s rear wing support is area of interest for the team as well it seems. During the tests in Barcelona different designs of winglet were trialled, and one failed.

One version (above) featured a single metal central support linked to the base of the Y shaped part of the rear wing pylon. Note the kink in the wastegate exit, a feature common to all of the 2016 Ferrari powered cars.

The location of the winglet suggests that it interacts with the exhaust plume. Another design (below) used featured what appears to be a 3D printed wing section cross bar.

Note the way the wing support passes through the tailpipe. It appears that rather than passing through the pipe the tailpipe actually splits in two around it. A closer look (below) shows the increase in thickness of the supports and the additional heat shielding.

A look at the C35 from the rear – note the angle of the upper wishbone and the top of the upright.

A look at the centreline cooling louvres on the Sauber, this is one of the few parts of the body work where the rules allow any openings.

At Melbourne a new 3D Printed brake duct was added to the C35.

A closer look at the roll hoop and ducting on the C35, the air filter is just visible in the main duct.

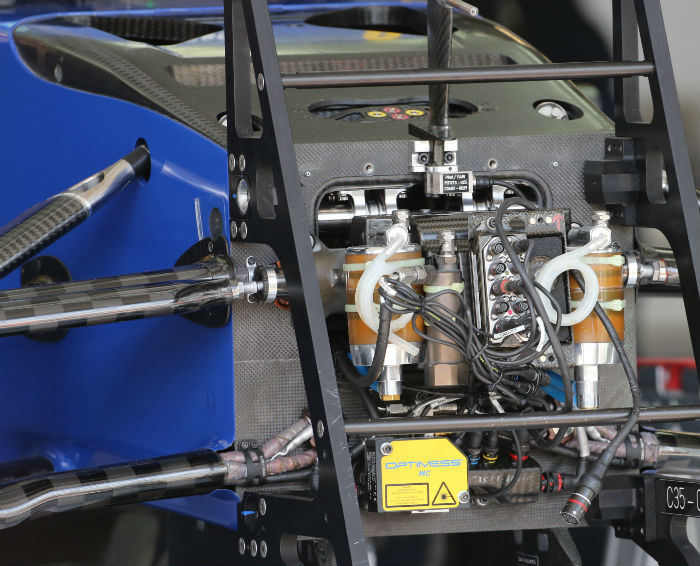

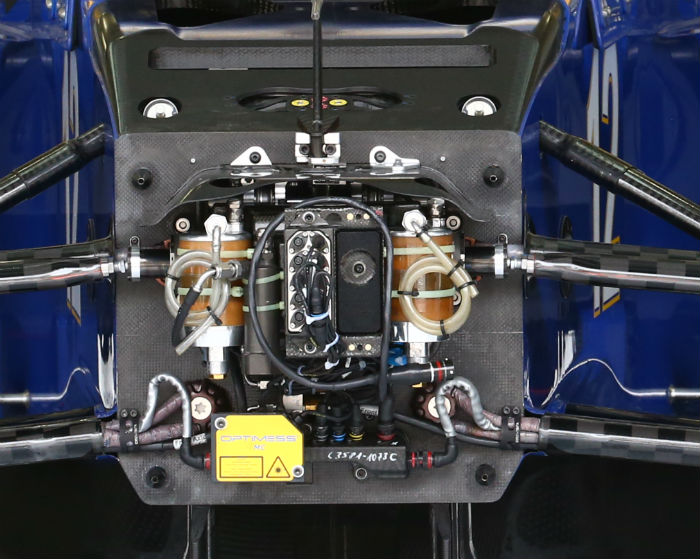

The front bulkhead of the C35 with the nose removed, the master cylinders are visible as is the Optimess laser sensor.

An unobstructed view of the rather tidy front bulkhead of the Sauber (below)

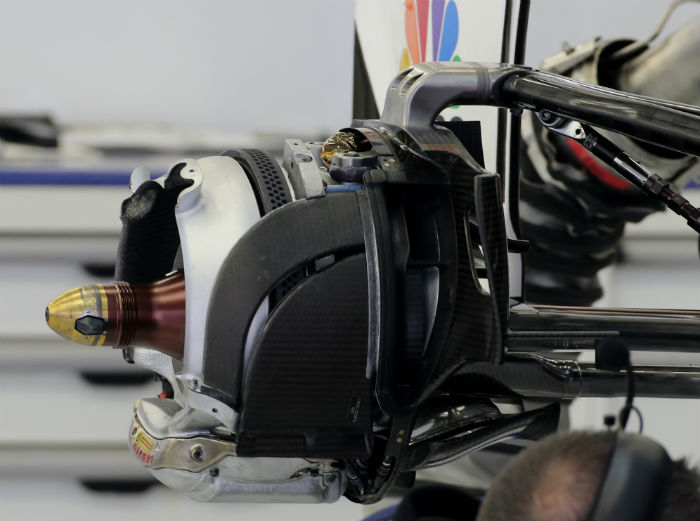

A look at the rear brake setup on the Sauber, while the other two cars which use the same transmission casing as the Sauber (the works Ferrari and the Haas) also share rear uprights the Sauber is a bespoke design. Note the right angle shape of the top of the upright.

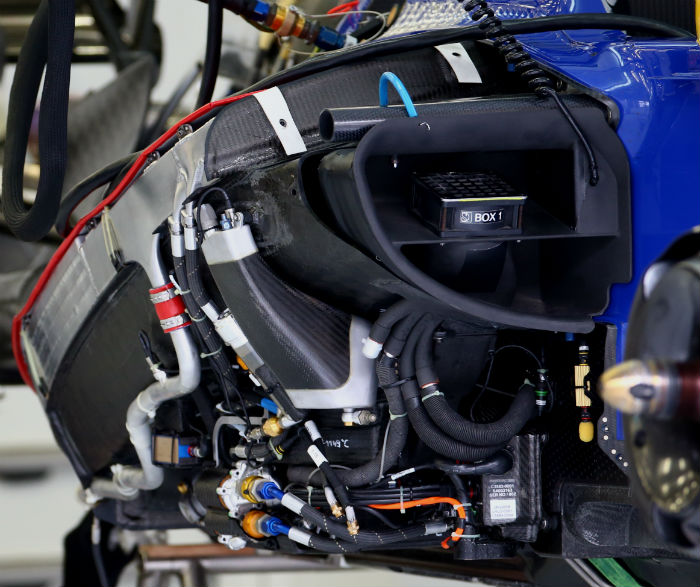

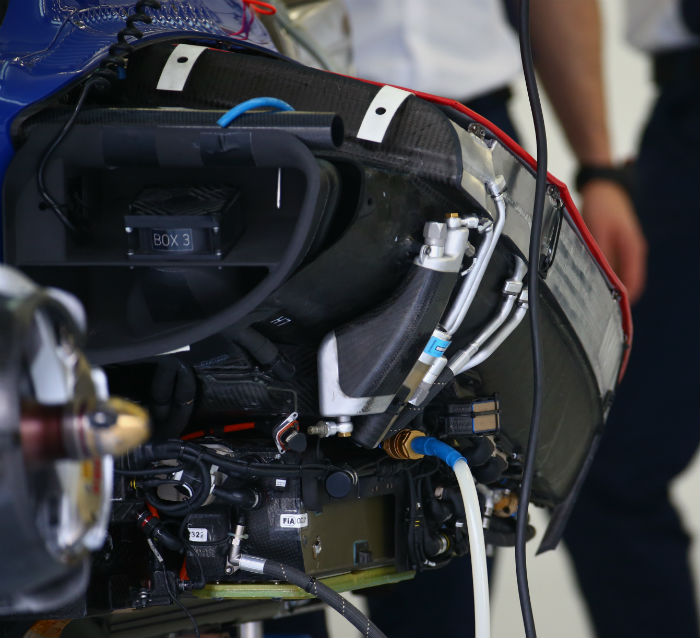

Here is that Ferrari carbon composite gearbox casing, the use of this does limit some of Saubers suspension design freedom but as it uses its own uprights it still has some, unlike Haas which uses an identical layout to the works Ferrari.

A look under the bodywork reveals some of the detail of Sauber’s cooling layout as well as the usual collection of control boxes in the volume under the main sidepod duct. In both images it seems that the lower impact structure is removed. Note how the upper side impact structure is located right at the upper leading edge of the main duct.

A look at the Ferrari transmission in its Sauber configuration(below). Note the tailpipe arrangement.