The McLaren MP4-31 is a clear continuation of the theme started with the MP4-30, this is perhaps not surprising as the 2015 car never really got to show its full potential. Opting for an online launch images of the MP4-31 were leaked well ahead of the planned time.

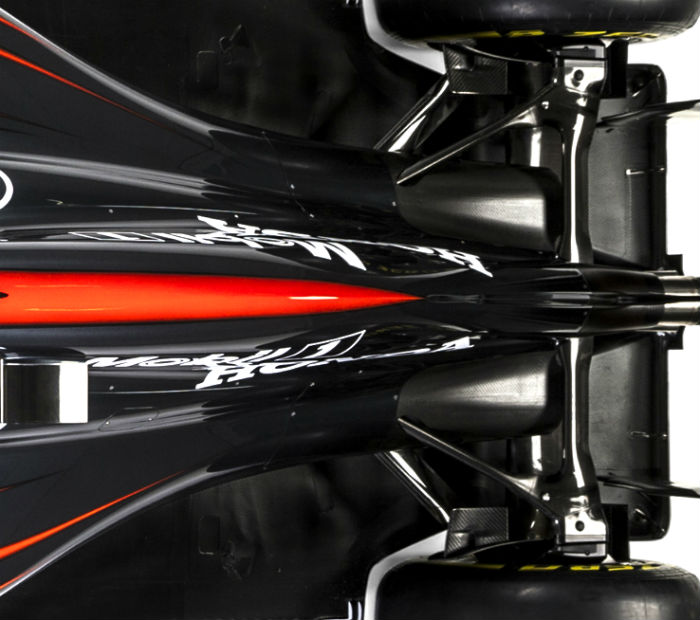

The overall car concept seems to be a second attempt at making ‘size zero’ work for the McLaren-Honda partnership and there are few immediately remarkable features about the MP4-31, though as the car develops it will become clear if it has all worked this time round.

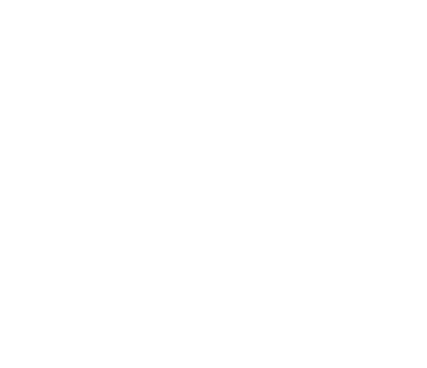

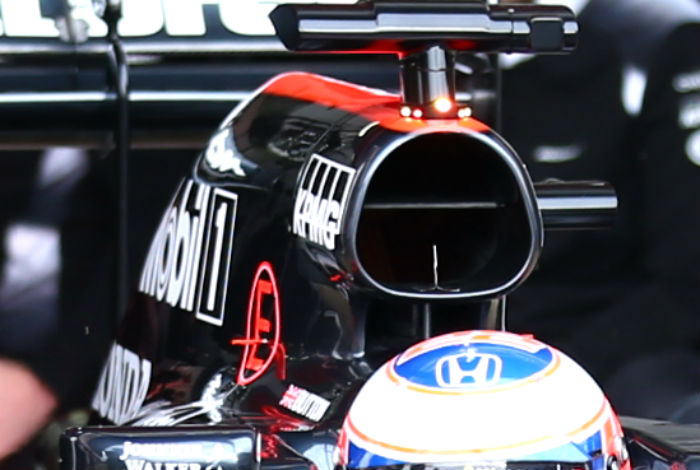

The nose design is similar to that of the MP4-30 late variant which allows for better under nose air flow than the ’15 Ferrari style long nose that the McLaren started with last year. Compare the 2016 nose (above) with the 2015 (below)

The 2016 car retains the S-duct utilised on the late season MP4-30 but in a mildly revised form as is to be expected.

The front suspension remains a pushrod actuated torsion bar layout, more on this once the front bulkhead is revealed. The rear suspension is again a pullrod layout

Around the cockpit the new rules see bigger head protection introduced but the biggest changes come around the roll hoop area. McLaren has adopted a new concept here, it has dropped the remote supports used on the MP4-29 and MP4-30 in favour of a very small aluminium stay under the main roll hoop.

This is something which will save weight high on the car and in turn reduce the centre of gravity but it is the result of some serious FEA time to get it through the crash tests. As with the MP4-30 the main airbox is split horizontally, with the lower segment feeding combustion air to the Honda V6 engine and the upper segment feeding coolers above the bellhousing. There is a small cooling duct under the main airbox inlet.

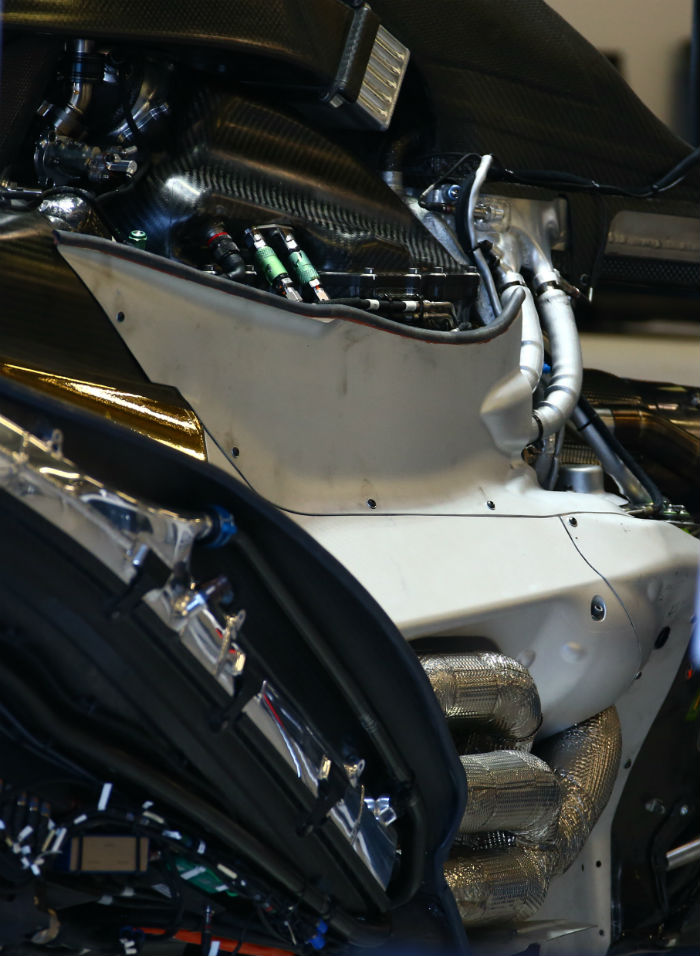

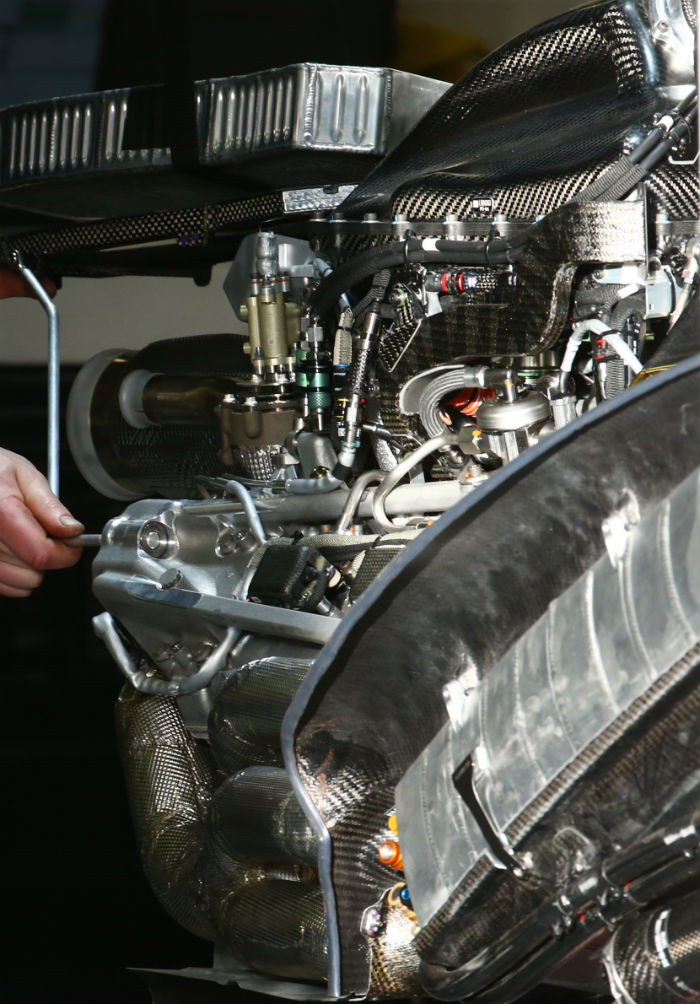

The rear end remains remarkably tight as McLaren attempts to benefit from the size zero concept. Honda continues with a very small power unit especially considering that it features a variable inlet (the smallest in F1 we think). Talk in the Spanish media of 200+ bhp gains year on year is nonsensical but Honda has taken a step forward. “We will not know for sure until the car goes out of the garage at the Barcelona test, but we have been continuing our progress from where we left off in Abu Dhabi. We are made specific improvements to the ERS areas where we saw our weaknesses last year. But honestly, with the current hybrid power unit, we have to run the car to see how much the system has truly evolved” Yasuhisa Arai claims. “The latter part of 2015 was still tough, but different from the first half. We continued to make progress with the ICE, and we figured out the root cause of our ERS weakness during the summer. We knew we could not make big hardware changes because of the regulations in 2015, but we were able to plan ahead to the development of 2016. Unfortunately, improving the ICE lead to some additional reliability issues, but we were able to learn a lot, and show some improvement on track as well.”

The 2016 Honda features a larger turbine but retains the Mercedes style ‘Pegasus’ split turbo, it is not clear if the Japanese firm has opted for a Birmann Log exhaust which it used in early 2015, or a more conventional layout as seen at the end of 2015.

Honda had to redesign its turbine at the end of 2015 as the new rules relating to the exhaust note forced them to have to add extra exits from the wastegates, something not possible with the 2015 layout. It appears from the pictures released so far that Honda has opted to use two small wastegate exits under the main tailpipe, in addition the rear wing support seems to pass through the tailpipe, an approach pioneered by STR last year.

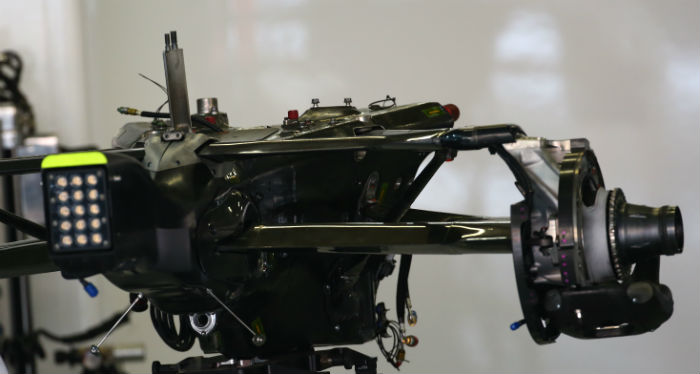

A look at the rear of the MP4-31, notable are the blended wishbone and driveshaft, and twin wastegate exit.

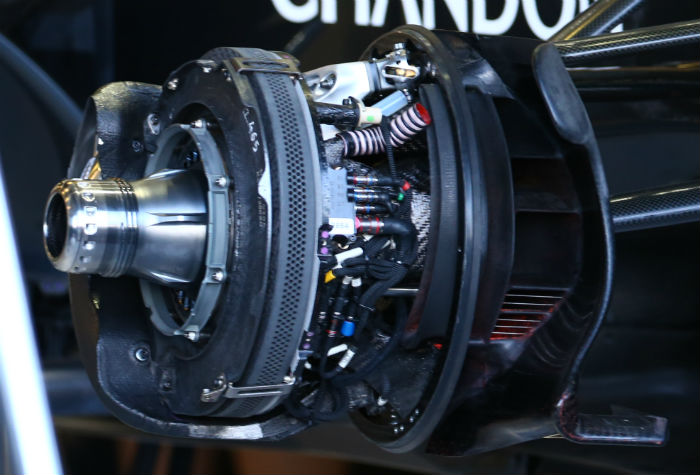

McLaren introduced a new specification brake duct during the first day of the test. Both the launch spec (above) and the new variant use a common base with various segments feeding air to various parts of the brake system plus also acting as a flow conditioner but the new version (below) has one duct fewer at the top and the new section appears to have been made using 3D printing perhaps with the popular Windform family of materials from CRP.

Note also the spacing of the front wishbones, something McLaren has likely done for aerodynamic reasons, while this is not a radical solution it does show that there are still aero gains to be had in this area. Mercedes and others have used a blended lower wishbone while both Ferrari and McLaren have attempted to get the same gains by using a pull rod front end. None of these solutions are great in terms of pure vehicle dynamics but the aerodynamic gains apparently offset the mechanical losses.

Here we get a better look at the airbox and roll hoop on the MP4-31, note the additional cooling duct below the roll hoop, it is split by the central roll hoop support.

The rear wing endplate of the MP4-31 is extremely complex, full of strakes and vents, clearly not a moments work in CFD or a PIV equipped wind tunnel.

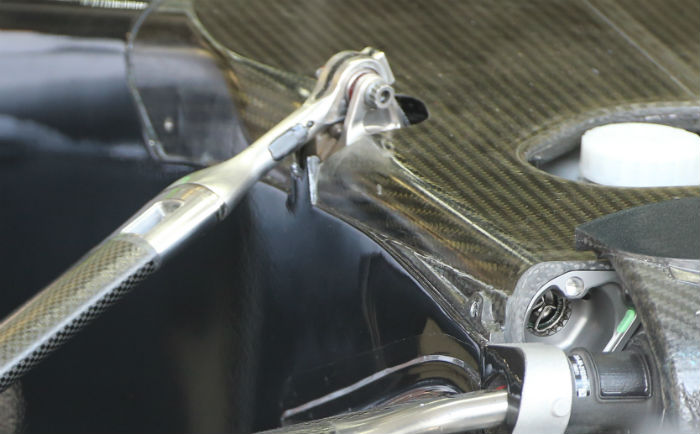

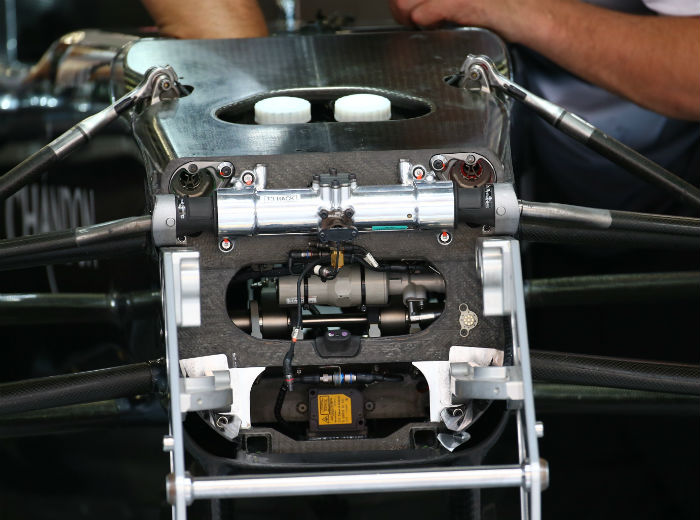

The inboard pushrod pickup on the McLaren sits above the chassis but under the vanity panel. Note the torsion bar on the lower right of the picture. It is located behind the steering rack and must be a tricky job to change.

The front brake setup on the MP4-31 with some of the ducting removed. The Akebono caliper (unique to McLaren in F1, though Toyota uses a similar product in LMP1) is mounted at the rear of the disc.

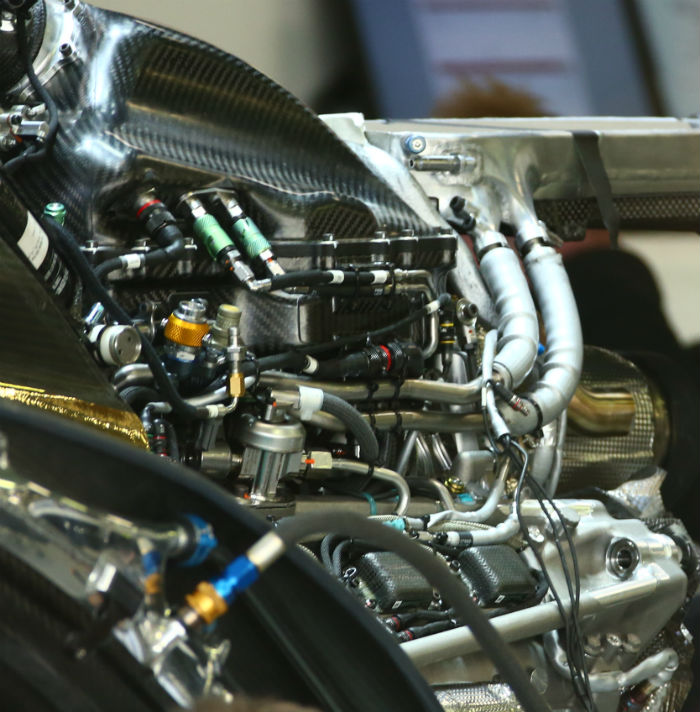

Honda has made a great effort with its 2016 power unit in an effort to correct the failures of 2015. Here we get a first look at the RA616H installation in the McLaren. Note the exhaust headers protruding beyond the heat shield. Honda copied the Mercedes Birmann log exhaust on the RA615H but late in 2015 dropped it for a more conventional header design (Mercedes dropped the log at the end of 2014). This new header design is a further development of that.

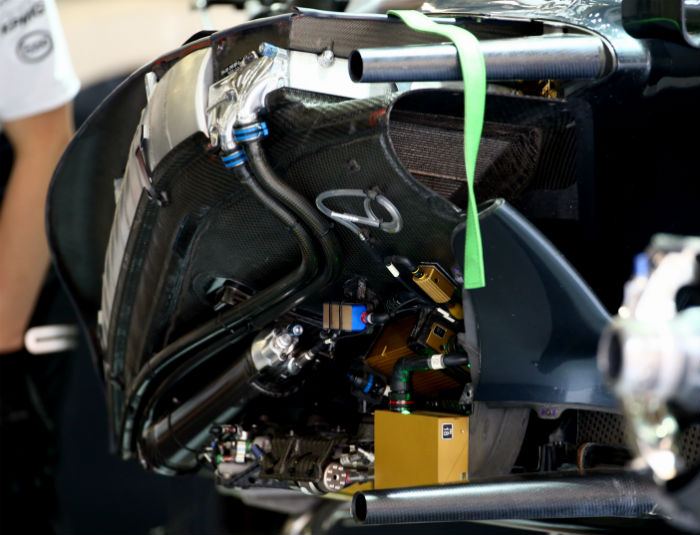

With the heatshield removed the head of the V6 engine is visible with the small plenum which contains the very neat Honda variable inlet system. The exhaust exit from the turbine is just visible as is one of the wastegate pipes. In 2015 the RA615H plenum alternated between a aluminium upper plenum and a poorly made composite part. The lower section remained aluminium all season. The RA616H however has a reshaped upper section in composite and the lower section is now also composite. The cooler fed by the airbox duct (along with combustion air) is visible in this image. It had been thought that this cooler was for the transmission but it is clearly cooling something on the power unit.

A look at the other side of the RA616H – note the intercooler in the foreground. Some of the wastegate components are visible in this image as is the 3 into 1 exhaust however the collector is not visible. It appears that it is located toward the front of the block.

The front bulkhead of the MP4-31. The power steering rack is clear to see as are the torsion bar. Some inboard parts of the suspension system are visible though the hole on the centre of the bulkhead. The master cylinders are mounted behind the suspension components close to the pedals, they are accessed via a aperture in the top of the tub under the vanity panel.

A look at the carbon fibre gearbox casing used on the MP4-31. It is built in house by McLaren and is not supplied to customer teams. Note the location of the brake caliper on the rear upright. McLaren uses calipers from Japanese company Akebono.

Under the bodywork of the MP4-31 you find all of the usual control boxes under the main sidepod duct, both upper and lower side impact structures are visible.