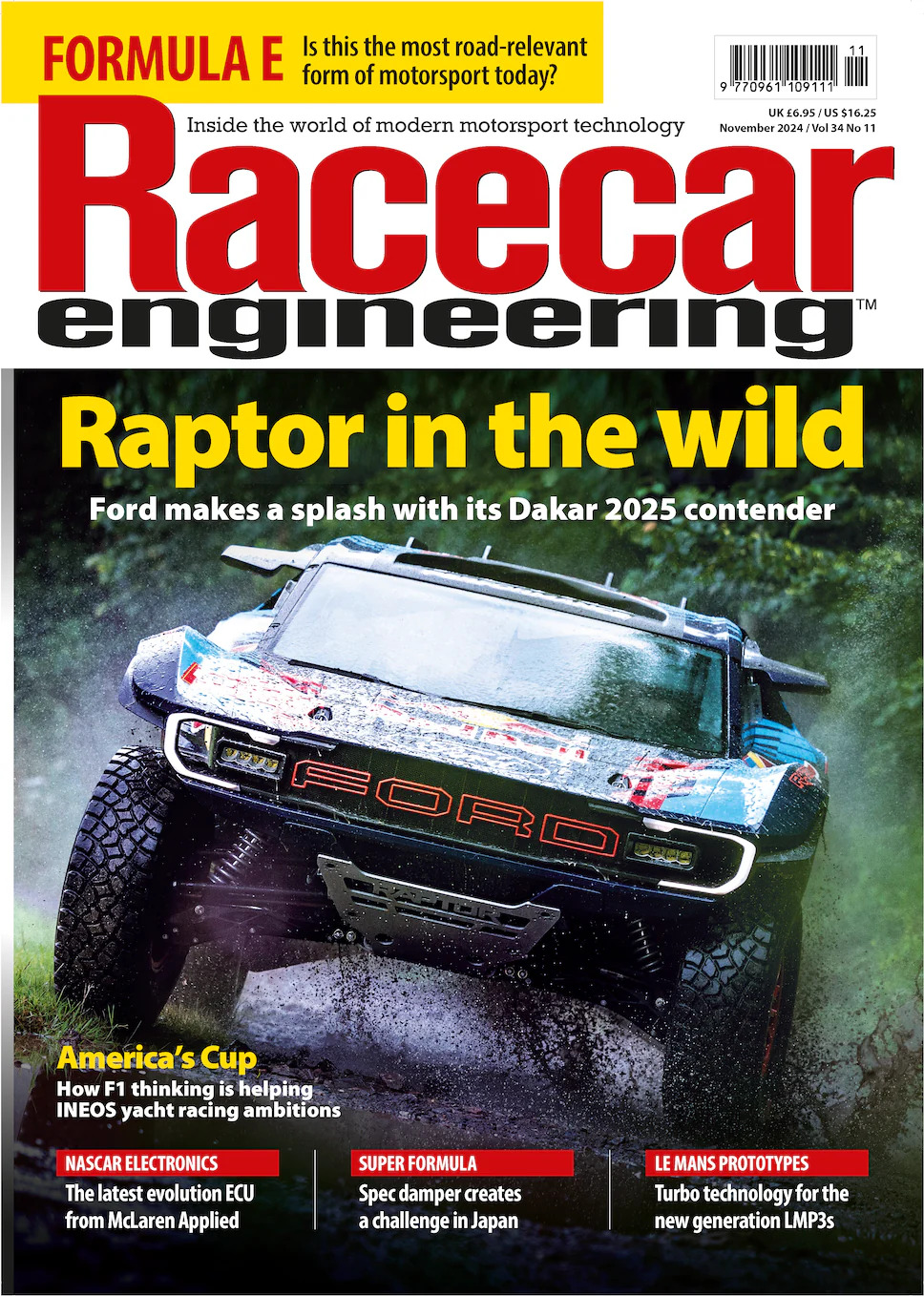

The 90mph winds of a storm named ‘Doris’ blew across the Silverstone circuit as the Mercedes F1 W08 made its official debut. Designed to maximize the performance opportunities offered by the new for 2017 technical regulations the W08 has specifically been designed to be versatile and have sufficient scope for an in season development rate expected to be among the fastest ever in Formula One.

Mercedes has changed the naming convention of its cars for 2017, dropping the word ‘hybrid’ in favour of ‘EQ Power+.’ The name EQ stands for “Electric Intelligence” (though surely that should be EI?) and according to the press release is derived from the Mercedes-Benz brand values of “Emotion and Intelligence”. EQ aims to make electric mobility simple, comfortable, safe and accessible for everybody. From the forthcoming facelift of the S-Class, all future Mercedes-Benz Plug-In Hybrids will carry the designation “EQ Power”. And the launch of the F1 W08 EQ Power+ makes the new F1 car the first Mercedes-AMG Hybrid to receive the “EQ Power+” designation, which will be used on all future Mercedes-AMG performance hybrids.

If last year’s W07 was all about refinement and elaborate, detailed evolution, the W08 project has gone back to first principles according to the team. With the car having to be designed before running the definitive 2017 tyres, and in some parts before the regulations had even been finalized, it was important to arrive quickly at a sound base architecture, while following a flexible, adaptable philosophy to allow scope for major developments during the season. With this in mind, only 17% of the components in W08 have been carried over from its predecessor, with the team’s main focus lying on optimizing the car within the new aerodynamic regulations.

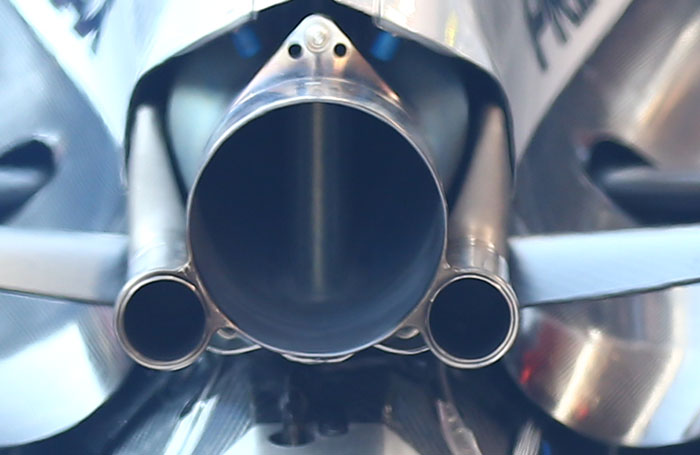

The M08 EQ Power+ is the fourth iteration of the turbo hybrid generation of Mercedes power unit and has been conceived to withstand the significantly increased physical loads and the more severe duty cycle which come as a result of the new chassis regulations. Its exact design is yet to be revealed (most pictures online are of older 2014-2015 era power units) but it is believed to retain the split turbo concept with the compressor at the front of the engine block and the turbine at the rear with the MGU-H mounted between them.

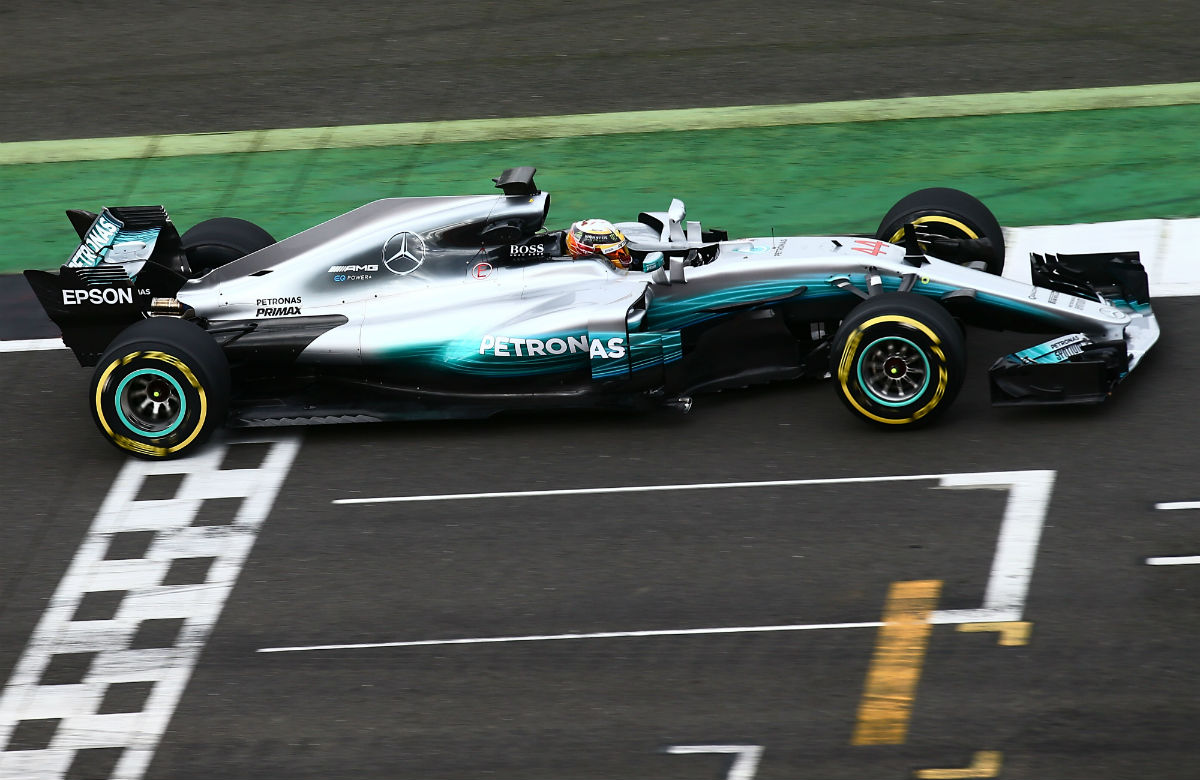

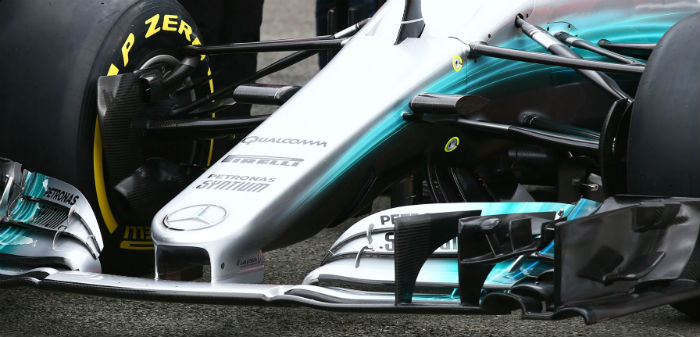

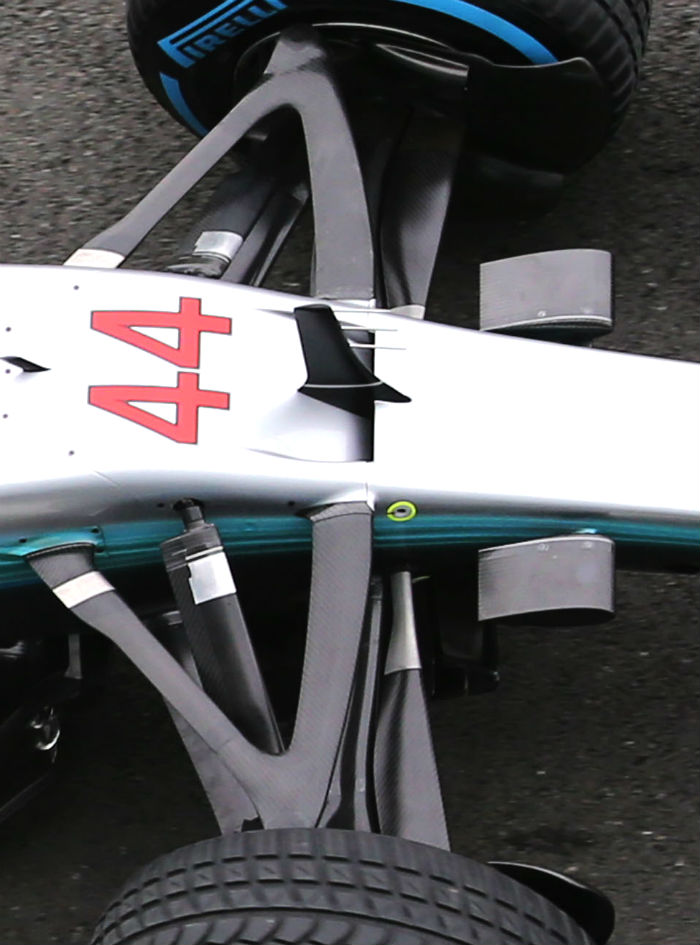

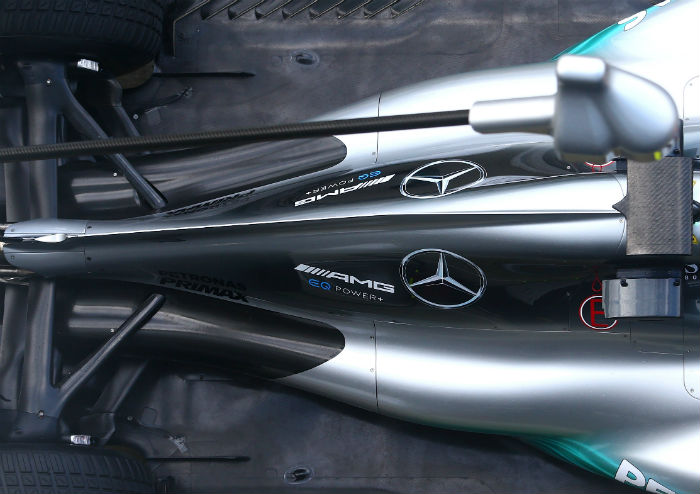

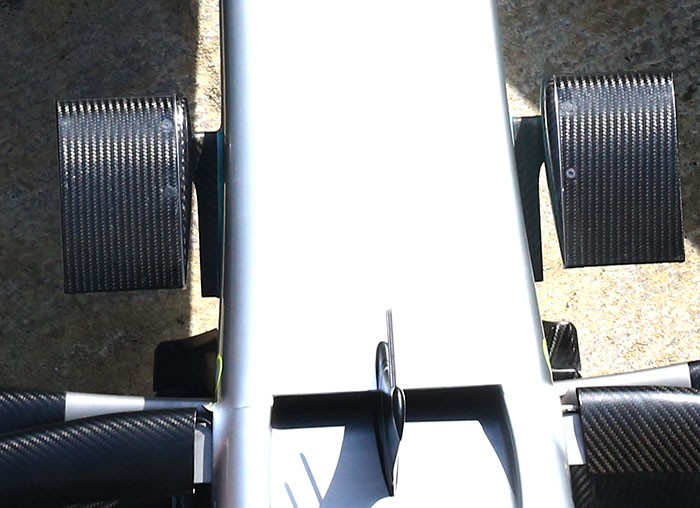

The ducted nose concept of the W08 is carried over from the W07 along with the overall shape of the nose and front impact structure though the front wing is of course wider and with a rearward sweep.

The outboard front suspension layout is conventional with pushrod actuated springs at the front, though the internal component layout is yet to be revealed. From above the exit duct on the top of the nose is clear to see, as is the outboard front suspension arm layout, note how the components are somewhat larger than those used on the W07, this is due to the higher loads which are the result of the new chassis rules.

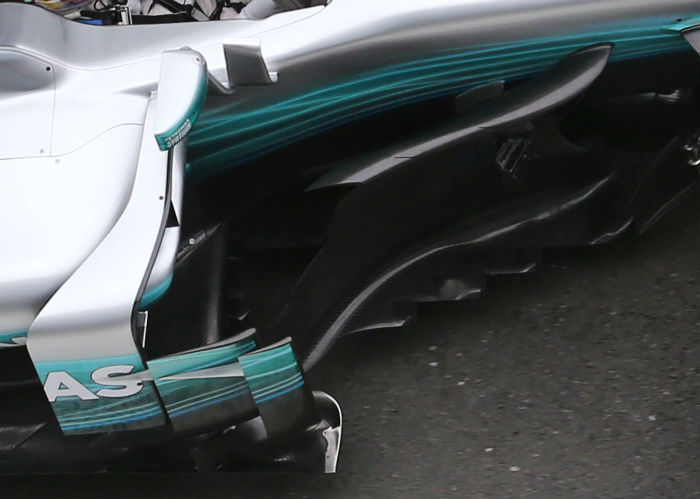

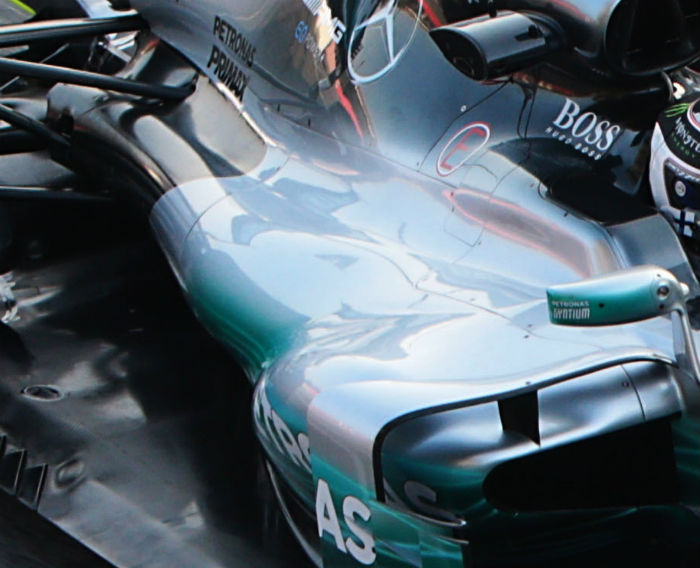

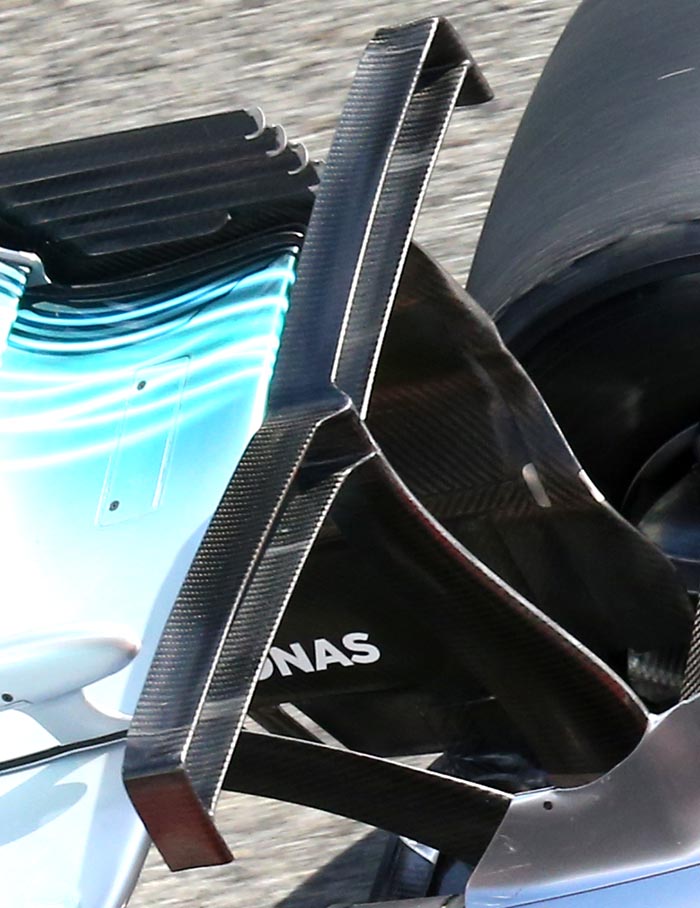

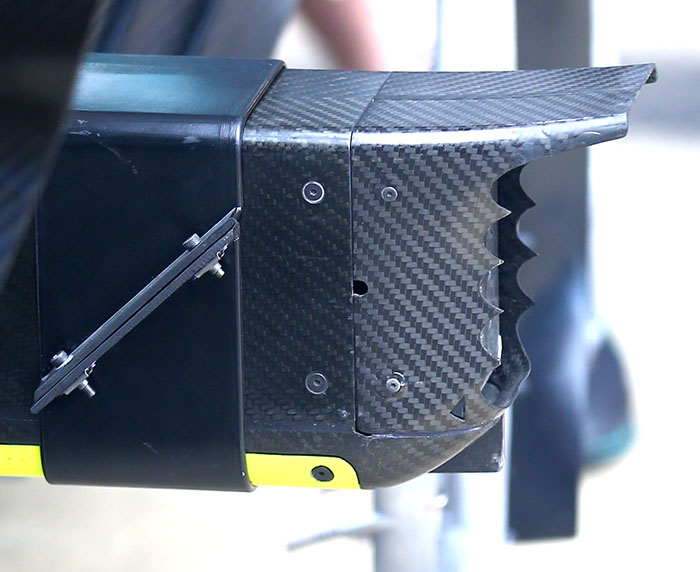

The area behind the front wheel is extremely complex on the W08, with a large bargeboard (complete with serrated leading edge), but also a pair of very long flow conditioners sweeping rearwards above it. The sidepod mounted ‘pod wing’ has two additional elements at the outer leading edge of the floor.

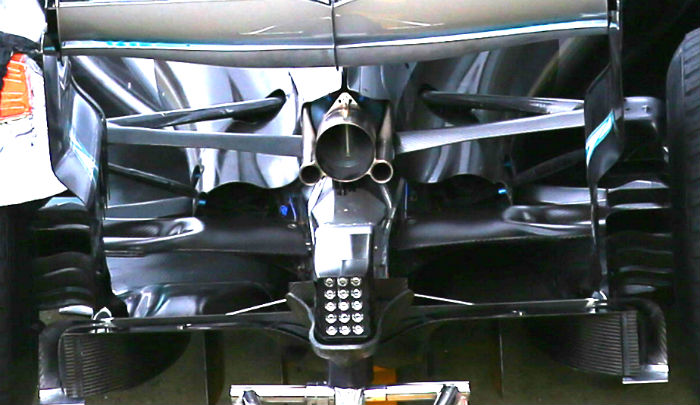

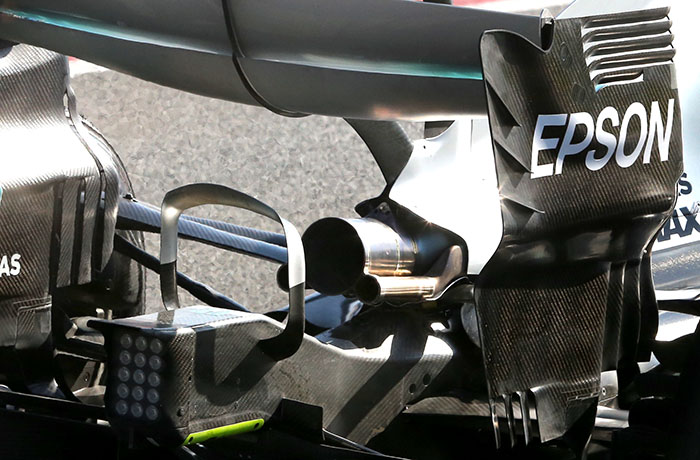

Looking at the outboard rear suspension the conventional pullrod layout is evident, note how tight the rear of the car is.

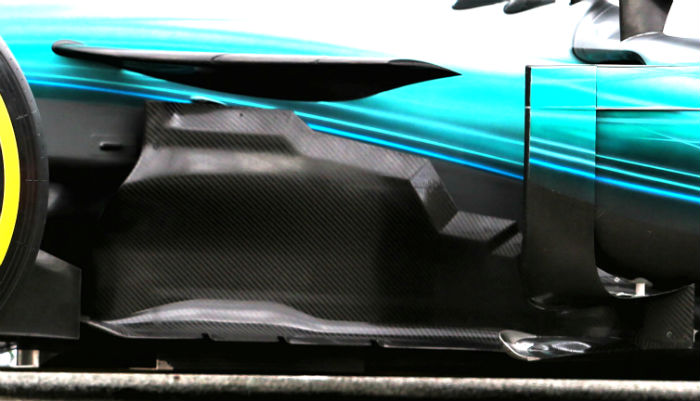

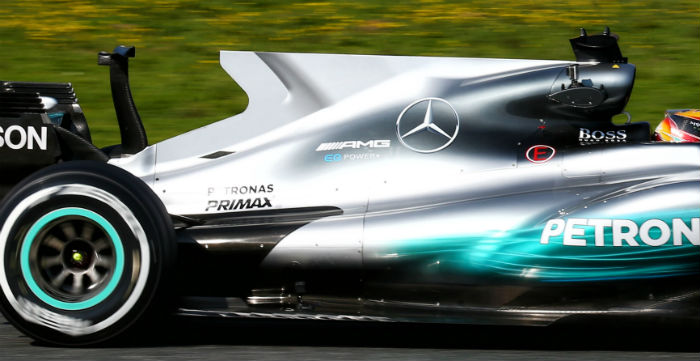

Behind the area where the main coolers are located the bodywork sweeps tightly inward, to the point where the rear of the car could be considered to be following the controversial ‘size zero’ concept used by Ferrari in 2014 and by McLaren in 2015 and ’16.

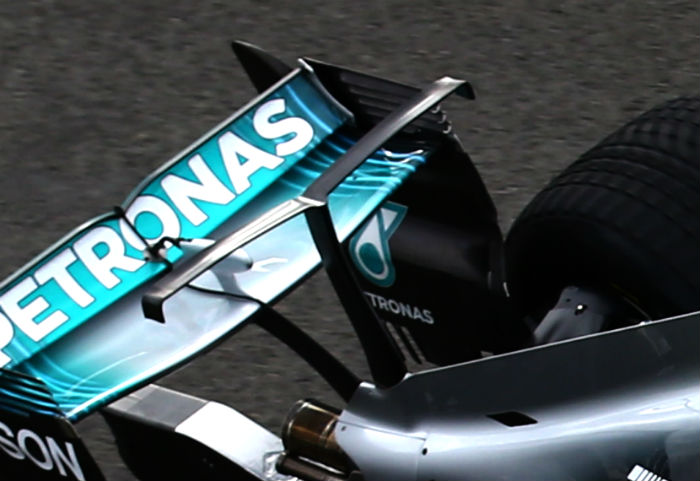

The W08 features a small cooling slot on the engine cover ahead of the rear wing support. Note the bodywork ahead of the main wing support, which appears to be a blanked off mounting for another component.

The exact nature of that component became evident during the shakedown runs at Silverstone.

The Mercedes ran at Silverstone with a very strange looking component on the engine cover, initially it was thought to be some kind of sensor mount – but it appears that it may in fact be an aerodynamic component. The dimensions of it seem to be the width and height of the old 2016 spec rear wing, perhaps exploiting a leftover from the old technical regulations carried over into the ’17 rule book.

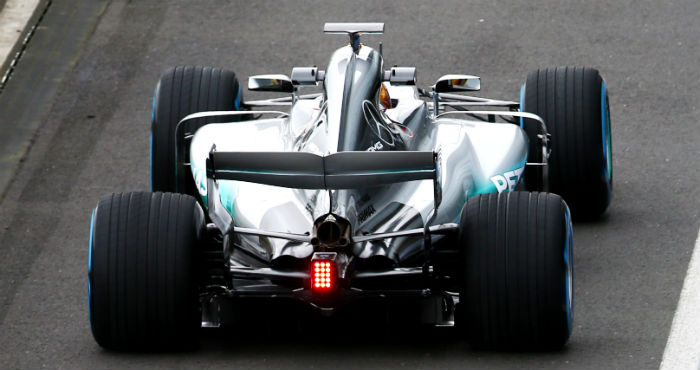

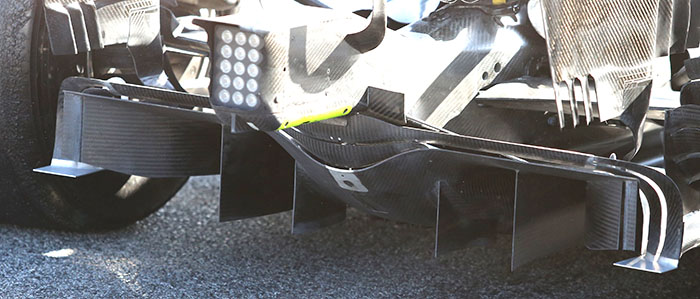

A look at the rear of the W08, note the much larger diffuser (allowed under the new regulations) as well as the rear wing support passing through the exhaust tailpipe. Finally note how the lower rear wishbone is blended

The segmented airbox concept carries over from the W07, with the two outer segments feeding cooling air to a heat exchanger mounted above the bellhousing of the car. This is used to cool the MGU-K & MGU-H. The central segment (between the A shape of the roll structure) feeds combustion air to the Mercedes V6. Note the serrated windscreen on the car.

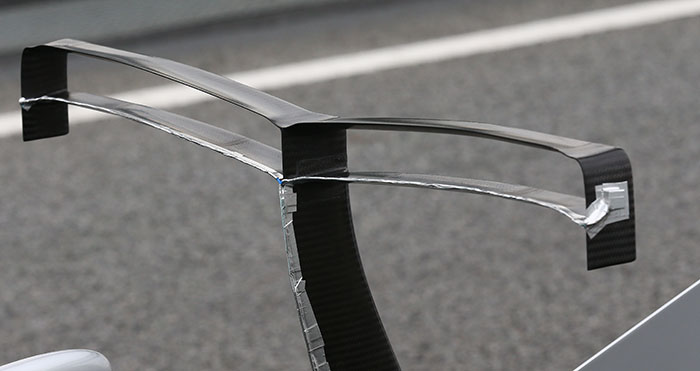

The roll hoop support again takes the form of an unusual ring shape, this too carries over from the W07, compart the 2017 design (above) with the 2016 (below)

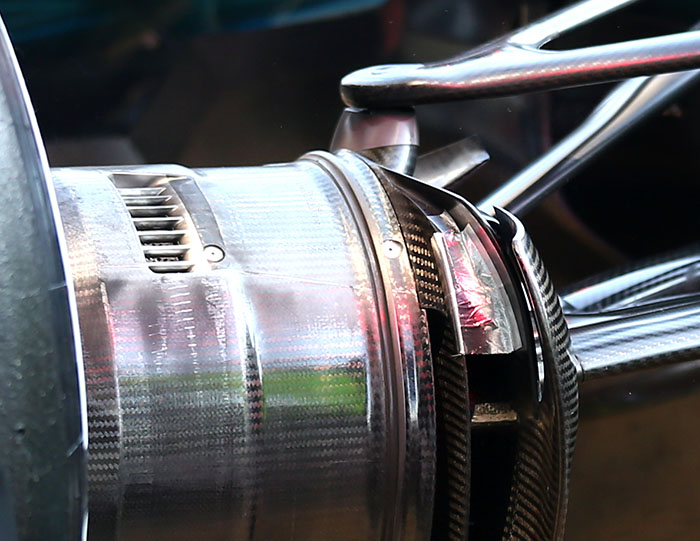

A look at the front brake duct area with all of its various turning vanes and winglets, this will be a major area of development in 2017.

During the first day of running the Mercedes was fitted with a engine cover fin which cleverly incorporated a large opening for cooling.

The opening is fairly large and is likely to provide a significant cooling gain.

As well as the aperture on the top of the fin a lump has appeared on the bodywork above the plenum, quite what it accommodates is unclear (below)

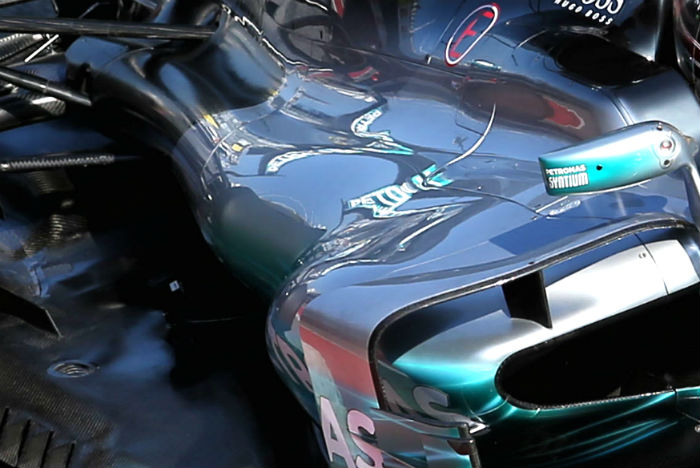

By opening up the top of the fin Mercedes as been able to tighten up its already tight sidepods significantly.

The version of the sidepod used in the morning running at the first day of the first test can be seen above, but when the fin with the cooling aperture was fitted in the afternoon a revised sidepod was also used, this was visibly much tighter (below)

Alongside the cockpit of the Mercedes is additional cooling in the form of two slits behind the drivers head rest and an interchangeable panel of cooling louvres in the usual location.

In the image above it is part blanked off, and below fully open. These cooling slots take advantage of a free zone in the otherwise restrictive bodywork regulations which outlaw openings on much of the bodywork.

A look at the camera mounting stalks on the W08. A number of teams are again experimenting in this area and further iterations are expected during the season.

A look at the outboard front wishbone pickup, it is mounted on a composite shrouded extension from the upright. Note how little of it is in contact with the metal part of the upright extension.

Another view of the same area with more of the brake duct area visible (below), in the upper duct an airspeed sensor can be seen. Note the small slot in the drum over the brakes for cooling the disc.

During the first pre season test Mercedes fitted a bi-plane version of its engine cover mounted winglet. It must be wondered how fast and far these designs will be allowed to developed before the FIA steps in.

The outer part of the biplane section has an interesting design with the wing section changing slightly before the end piece (below).

Mercedes studied the performance of the wing during testing, the silver tape covers the wiring leading to sensors on the outer edge of the winglet.

A look at the rear of the W08 showing a number of interesting aerodynamic details on the rear wing endplate.

A small winglet was fitted to the rear crash structure, something of which there will be likely a wide range of differing designs utilised during the season. Note the small heat shield between the tailpipes and the top of the transmission casing/rear impact structure.

A look at how close the wastegate exit pipe sits to the suspension arm, note the heat shield between them.

Here it can be seen very clearly how the rear wing support passes through the main tailpipe.

A look at the Mercedes diffuser. Note the metal outer most components.

The trailing edge of the rear impact structure is fitted with a carbon fibre extension complete with a saw tooth edge.

The rear floor is an area of development for Mercedes, the array of cut outs leads to a large cutout just ahead of the tyre, it is thought that these features are designed to reduce the impact for a vortex from the base of the rotating rear tyre on the performance of the diffuser.

Holes in the rear of the floor are not legal under in the regulations so all of the slits on the edge of the floor must be linked to the outer edge. The shadow cast on the ground reveals that the clearly all are in this case.