Renault RS19 Launch

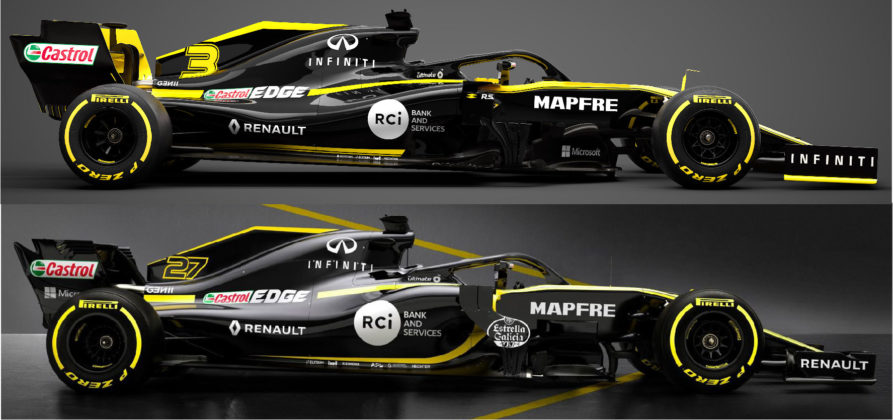

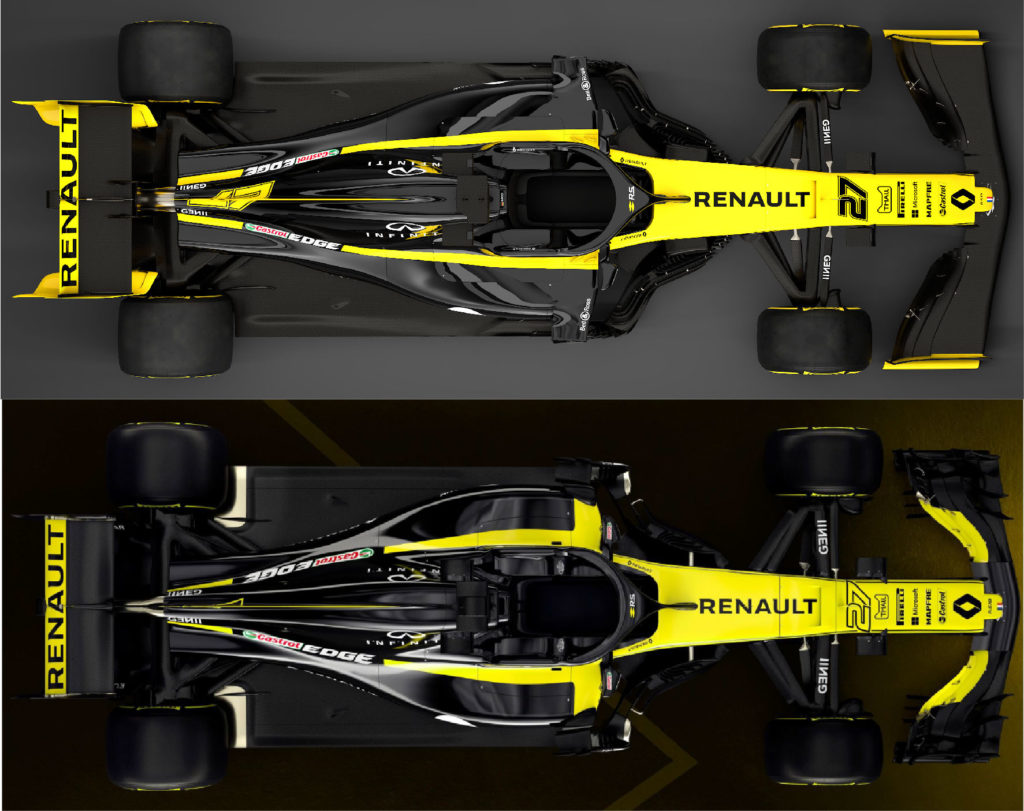

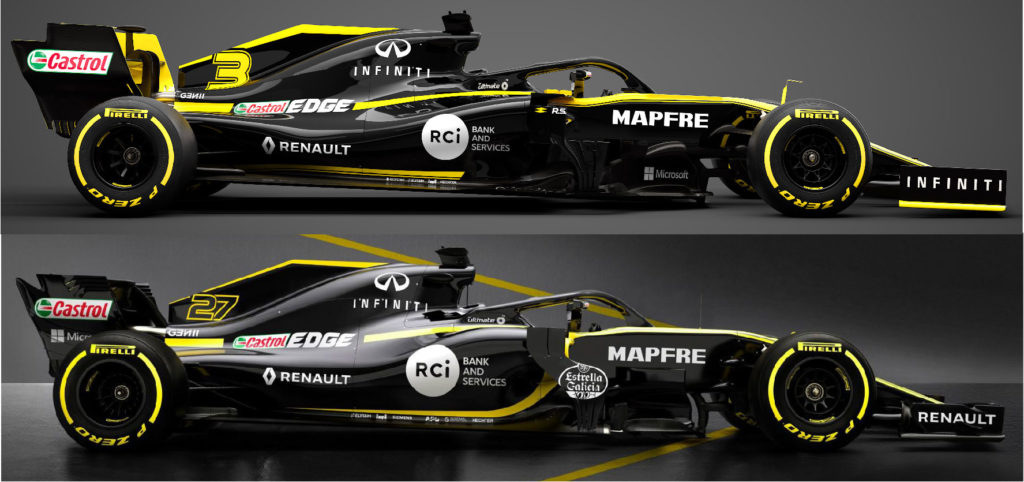

The Renault F1 team pulled the covers off their RS19 racer which will fight for that all important 4th place spot in the constructors championship for 2019. Although the car revealed at the launch back at the teams’ HQ in Enstone was more of a new livery then a new car – with only the digital renderings hinting towards the 2019 design.

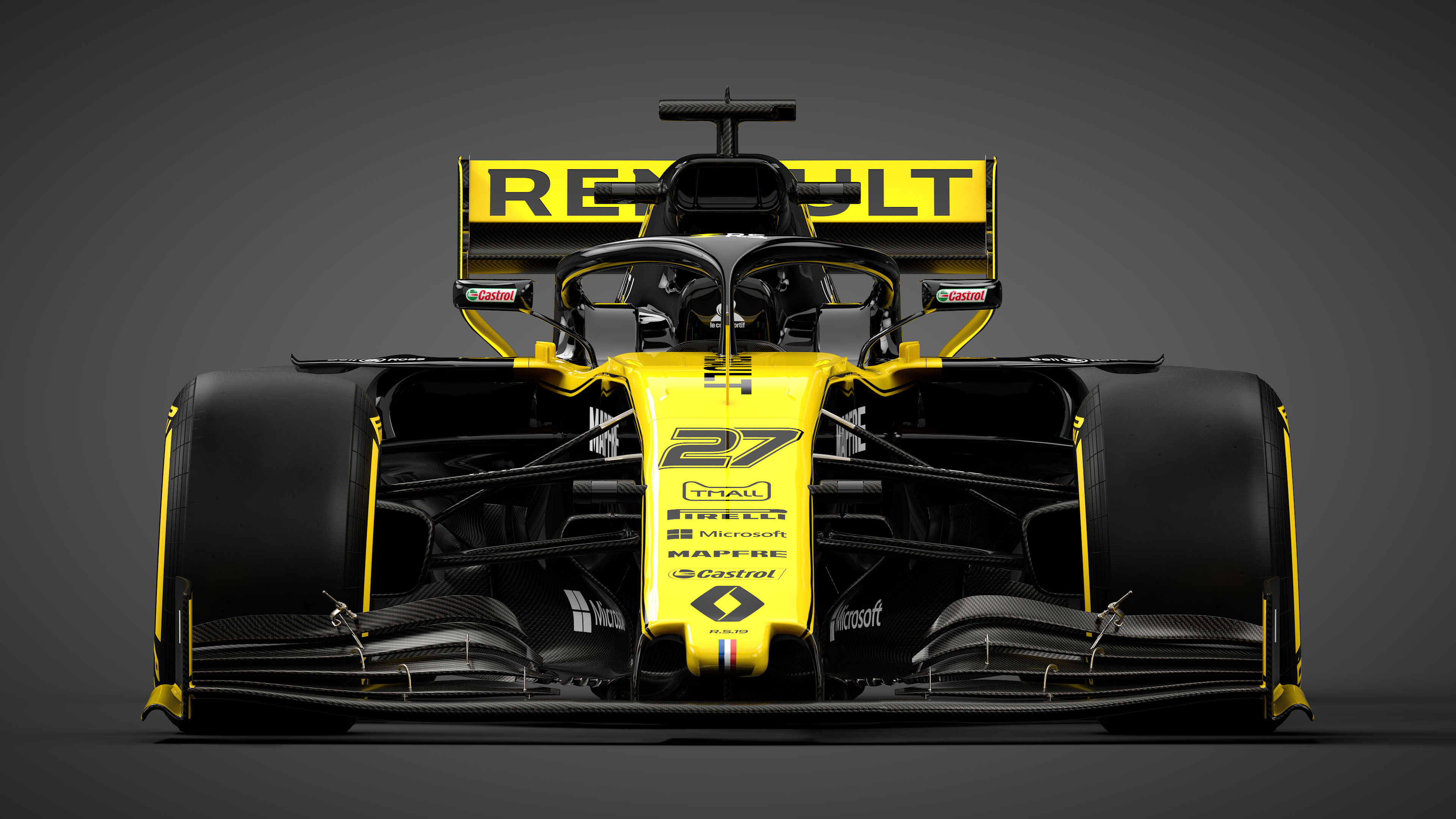

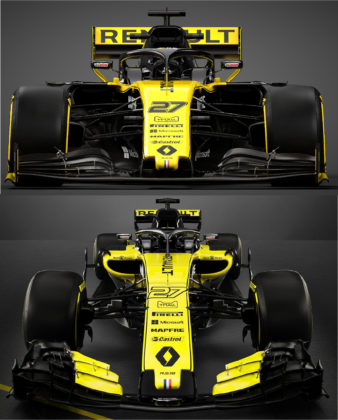

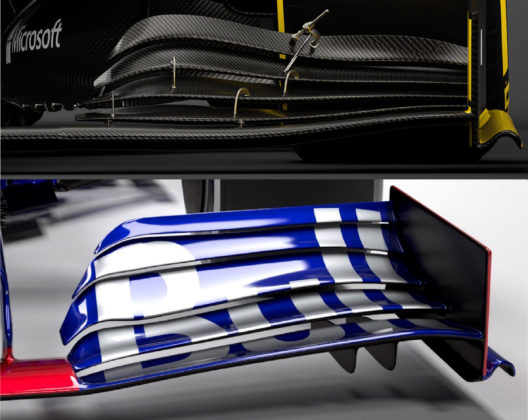

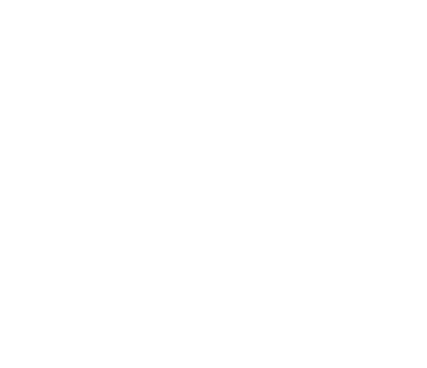

The most noticeable rule change for 2019 is the front wing. The front wing width between the central reference plane and the outer edge has increased by 100mm both sides, resulting in an overall front wing increase of 200mm which now matches the full 2m width of the car as shown below. Furthermore, the specified area of the front wing can now only contain endplates, a maximum of five closed main elements, a maximum of two front wing strakes and auxiliary components such as a fairing for the tyre temperature sensor and the necessary brackets. Gone are the days of the complex arrays of winglets and elements that sit on the outboard section of the front wing.

‘The front wing with the much wider span, and the fact we are very limited on what we can do with the profiles, furniture and endplates changes a lot,’ explains Nick Chester, Chief Designer at Renault F1. ‘I think teams will be able to generate wing load in a straight line but trying to get everything working when you have yaw and steer on there is going to be really tough. It’s going to take quite a lot of work to get things working the way you want them to and get the right flow structures down the side of the car. That means that front wing area is going to be crucial, and with the air ducts changing too we can’t turn the flow as much as we used to in that area.’

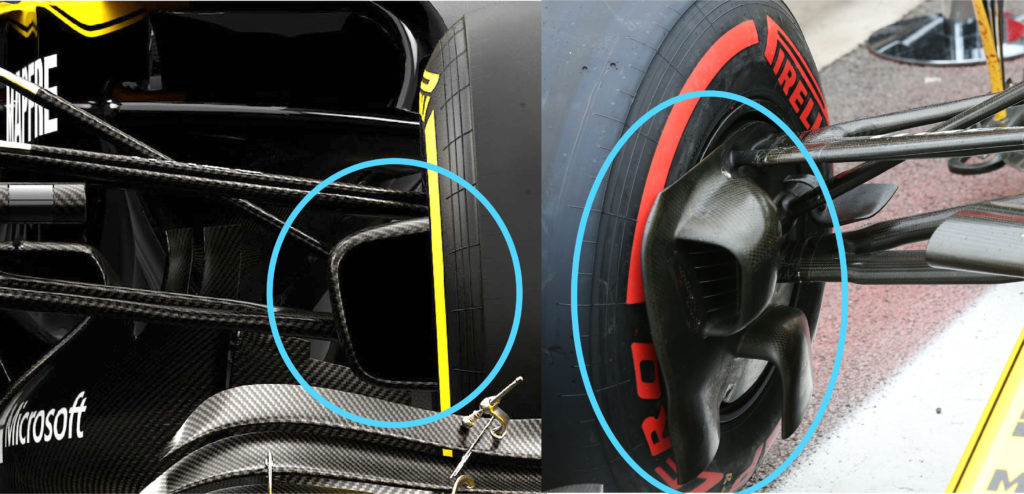

‘There may be a few little things we can do and we are looking at those,’ highlights Chester. ‘Ultimately it could all put more reliance on the bargeboard system because if you can’t turn the flow with the front wing you might be trying to get a good deal of outwash with the sidepod vane system. All that whole area, including the front wing and brake ducts will be crucial in making the rear of the car work properly.’

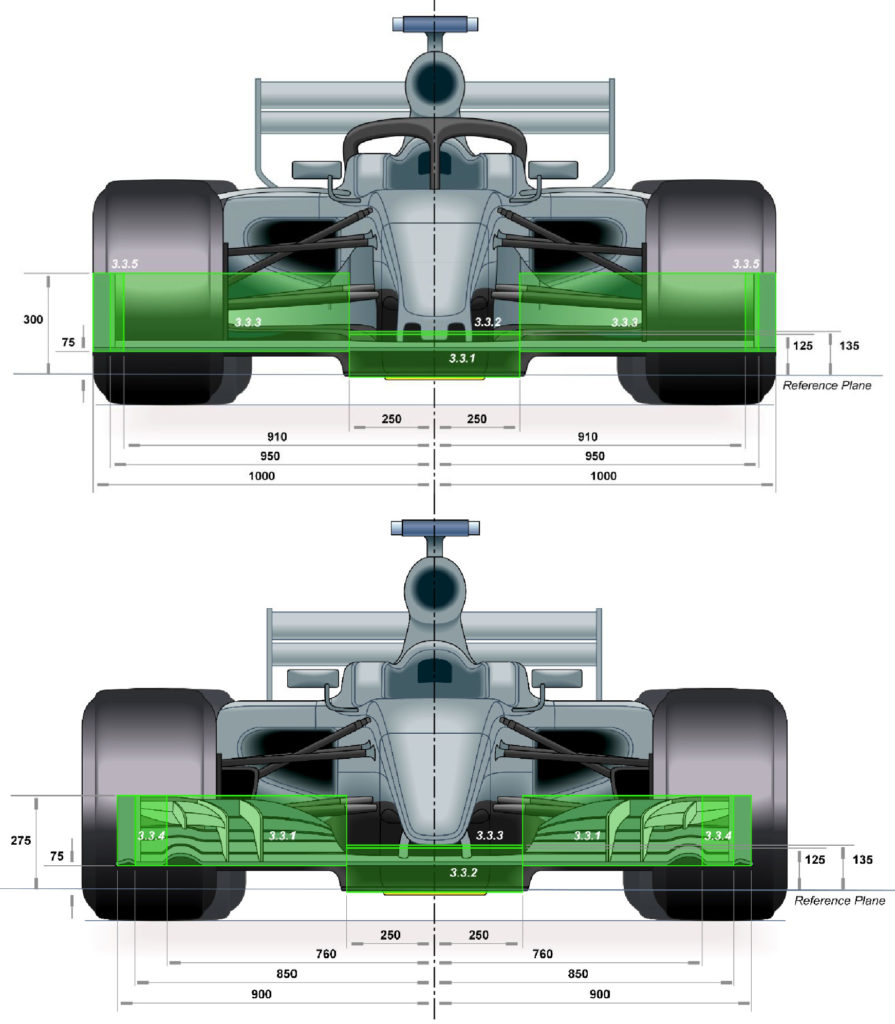

The front wing of the Renault RS19 features main elements that have significantly more curvature along the length when compared to Toro Rosso’s STR14, which appear to be much straighter. Furthermore, the mountings of these elements are evident on the RS19, but are either hidden or on the underside of the STR14.

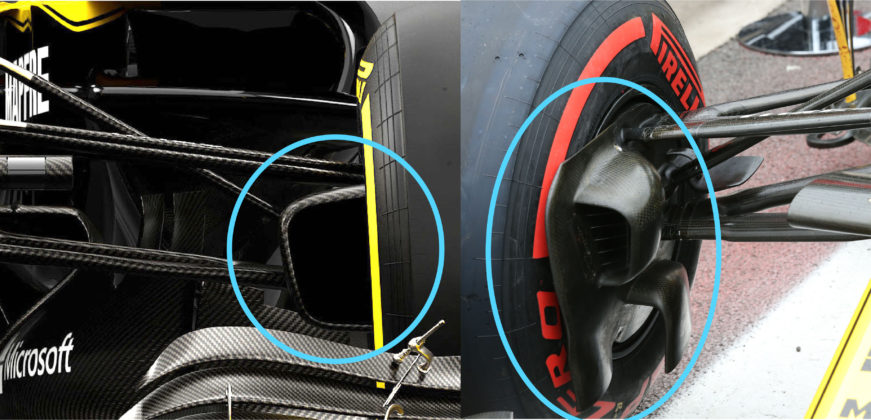

To ensure teams can’t capitalize on the outwashing of the front wing, the regulations have also restricted brake duct design. Only one single cooling aperture, of 50mm circumference, is allowed and so the complex assemblies of turning vanes and winglets of 2018 have been banned. To avoid the ‘blowing nuts’ of 2018 which contributed to the outwash effect, the regulations now specify that no air is permitted to pass through an area 105mm in diameter from the centre of the wheel nut. To eliminate this aerodynamic tactic further, all apertures where the suspension legs, upright elements or brackets meet the ducting must be sealed so no air can pass through them. Last year, teams were using these mounting points to feed air through this area.

However, development in wheel rim and brake cooling design is now more important than ever. ‘It is even more important with the 2019 rules because you are struggling to get the front wing to outwash the air as much as you would like,’ explains Chester. ‘So if you can do more in the wheel it becomes even more important.’

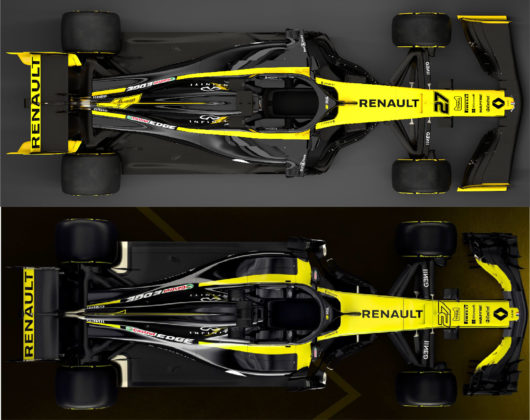

A further impact of the 2019 regulations is a reduction in bargeboard height by 150mm as well as a 100mm move forwards, both of which can be seen in the comparison below.

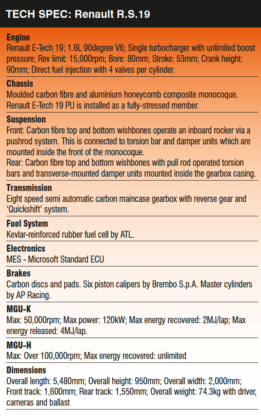

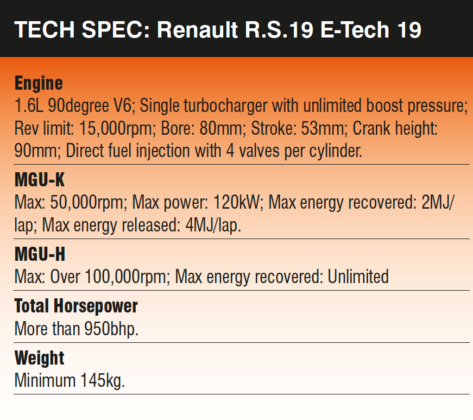

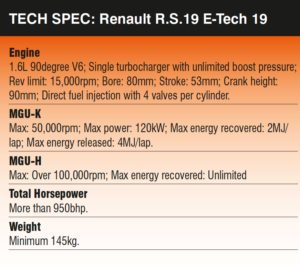

The Renault E-Tech 19 PU will be at the heart of the RS19. ‘We confirmed last year that the direction we were developing the engine was the right method and that meant we could continue our efforts into 2019,’ says Remi Taffin, Engine Technical Director at Renault F1. ‘Viry has been very busy over the winter and we have worked as late as possible to embed as much performance and reliability. We have now built the test engines and we are about to sign off race engines. We’re satisfied with what we’ve been able to produce. We’ve pushed on the pure performance element while also keeping a hand on reliability.’

The Renault E-Tech 19 PU will be at the heart of the RS19. ‘We confirmed last year that the direction we were developing the engine was the right method and that meant we could continue our efforts into 2019,’ says Remi Taffin, Engine Technical Director at Renault F1. ‘Viry has been very busy over the winter and we have worked as late as possible to embed as much performance and reliability. We have now built the test engines and we are about to sign off race engines. We’re satisfied with what we’ve been able to produce. We’ve pushed on the pure performance element while also keeping a hand on reliability.’

Although these initial shots of the RS19 might not look too different to last year’s RS18, Renault as a team has changed dramatically. ‘We introduced an extensive rebuilding programme in Enstone with new buildings and new production tools, including a wind tunnel upgrade, a new ultra-modern operations room, new chassis machine tools etc,’ explains Cyril Abiteboul, Managing Director at Renault F1. ‘A huge recruitment drive has also increased our workforce by 50%. Efforts have been made at Viry as well, with new investments in engine dynos and also in construction of a new building due for completion next year aimed to rehouse all the engine assembly.’

Although these initial shots of the RS19 might not look too different to last year’s RS18, Renault as a team has changed dramatically. ‘We introduced an extensive rebuilding programme in Enstone with new buildings and new production tools, including a wind tunnel upgrade, a new ultra-modern operations room, new chassis machine tools etc,’ explains Cyril Abiteboul, Managing Director at Renault F1. ‘A huge recruitment drive has also increased our workforce by 50%. Efforts have been made at Viry as well, with new investments in engine dynos and also in construction of a new building due for completion next year aimed to rehouse all the engine assembly.’

These new toys include new flow measurement and analysis tools which will be utilised in the teams Wind Tunnel; advanced machining centres so that the chassis can be machined to tighter tolerances; a new gearbox dyno which is multifunctional and capable of testing 1) The gearbox with the engine 2) The engine on it’s own 3) The ERS system on its own 4) The engine together with the rear end of the car.

Overall, Chester believes that these 2019 rule changes are a rung on a ladder to 2021. ‘Obviously, in one year you could not do all of the changes which are planned for 2021,’ he says. ‘But from what we’ve seen so far I think the 2019 rules will make a small difference. It’ll go in the right direction, so the following [one car behind another] will be a little bit improved, but we’re probably going to have to wait until 2021 to see what the full package can deliver.’

And we will have to wait until the Australian Grand Prix before the final design of the RS19 is truly revealed.